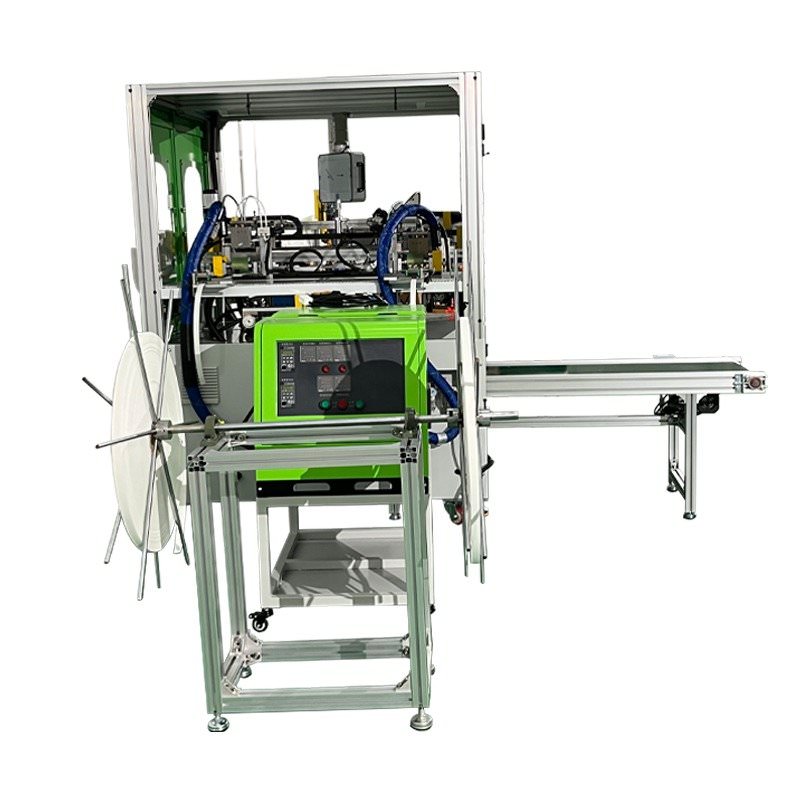

Automotive cabin air filter edge bonding machine ES-061

The automotive cabin air filter edge bonding machine ES-061 is designed for automatic feeding cabin strips ,automatic coating cabin strips with hot melt glueand automatic cut glue- coated cabin strips to length and bonding glue -coated cabin strips with two side edges of cabin air filter papers which makes a good quality edge bonded cabin air filter without dislocation. this cabin air filter edge sealing machine is suitable for products with dimensions ranging from 150-400mm in length, 150-300mm in width, and 10-60mm in height. . It applies with two working molds in shift to increase productivity , the out productivity is 240- 500pc /hour .

Youtube video

This cabin air filter strip gluing machine had been equipped with a hot melt glue machine which melts the glue in 170 degrees after 30 minutes of preheating time . the cabin strips is coated with hot met glue evenly by the good quality coating device which controls the stable output amount of hot melt glue .

The glue application strip width is adjustable from 10-60mm. It operates on 220V voltage with an air pressure requirement of 0.6-0.8MPa and has a power consumption of 20KW.

This Automotive air filter edge gluing machine also applies with PLC touch screen for easy operation and stable performance , the processed cabin air filters are good quality joint and without dislocation ,high productivity and labour saving .

【Technical Data】

Product Name: Automotive cabin air filter edge bonding machine

Model: ES-061

Functions: automatic double-side edge bonding + automatic glue coating+

automatic edge strip cutting+ automatic feeding material

Applicable Product Range:Length: 150–400mm ,Width: 150–300mm ,Height: 10–60mm

Glue coating width: 10–60mm

Voltage: 220V

Air Pressure: 0.6–0.8MPa

Power: 20KW

Efficiency: 8–15 seconds per unit

Molds : For fixing the folding line distance

Number of Molds Used: 2pcs

Equipment Dimensions (LWH): 2000x1900x1800mm

Machine Weight: 480KG

【Product Advantage】

1,Auto Feeding cabin strips + Auto coating strips with hot melt glue+ Auto cut cabin strips to length + Auto join glue- coated cabin strips

with air filter paper edges .

2, Even coating of hot melt glue and Good quality bonded cabin air filter without dislocation on the joints

3,High productivity and labour saving compared to manual edge bonding the cabin air filter .

【Product Details】

1,Hot melt glue machine , the machine had been equipped with a hot melt glue machine for melting the glue to be coated on the

cabin strips . both strips are loaded on the holder shelf

2,Hot melt glue coating , the automotive air filter edge gluing machine applies with good quality coating device which ensures the

stable output amount of hot met glue and even distribution and coating of hot melt glue on the cabin strips

3, Molds , the pleated air filter paper is placed manually on the molds , the purpose of the mold is to fix the folding line distance

of cabin air filters .

Two molds work in shift to increase productivity .

Stick both air filter edges with strips automatically by the two presser which holds the two glue-coated strips .

The finished edge bonded cabin air filter will be taken away from the molds and placed to the transport bands for issue out and collection.

4,PLC touch screen ,this cabin air filter strip gluing machine applies with PLC touch screen for easy operation , customer can set

machine working speed and manual control of the machine and any alarm code can trace to specifical problem and with solution

accordingly .

Front View

Side View

Side View

【Warranty 】

As a automotive cabin air filter edge bonding machine supplier , all the spare parts of the machine will have one year of free maintainance

by changing the spare parts for free and free shipping of spare parts to overseas clients starting from the issuing date of commercial invoice

after on line diagnosis .

【Packing】

1Set/Wooden case ,foam paddings will be put inside wooden case for safe overseas shipping

Home

Home

Inquiry Now

Inquiry Now Download

Download