Automatic rope coiling binding machine ES-053-2

This automatic rope coiling and binding Machine is an innovative and efficient machine designed for the automatic coiling, binding, and cutting of ropes. It is suitable for ropes with diameters ranging from 3 to 12 mm and offers a range of customizable options to meet specific production needs. The machine is ideal for industries requiring high-speed and precise rope bundling.

Youtube video

a short video to understand how it works

The entire proces of this hemp rope coiling binding machine from rope feeding to coiling and binding—is completed seamlessly gathered in one machine , the machine ensures precise cutting of rope to the required length and accurate binding of the coiled rolls.

Users can easily adjust the coiling diameter, height, length, and production speed. Additionally, the head and tail length of the rope can be set according to specific requirements

The winding process involves a clip scissor that performs dual functions—clipping the rope end and cutting it to the desired length. The ranking unit adjusts the height of the rope during the winding process, while the adjustable winding bar distance determines the length of the rope roll.the binding wire is fed to the required length on the wrapping hands, which wrap the wire around the coiled rope. The collection hand then takes over the wire-wrapped rope roll . This automatic rope coiling binding machine is equipped with bundling hands that clip and rotate the bundling wires, securing the rope rolls efficiently

The winding distance ranges 150-250mm and binding rope diameter ranges 10-40mm , the average productivity is 4S per piece taking 2 meter coiling length as example .

This automatic rope coiling and binding machine is an excellent solution for businesses that require high-speed, efficient, and precise rope bundling operations. Its fully automated functions and customizable settings make it a versatile and productive tool for rope manufacturing and related industries

【Technical Data】

Product name :Automatic rope coiling binding machine

Model No. : ES-053-2

Suitable rope diameter: 3-12 mm

Cutting Length:

5-20 m (for 3-5 mm diameter)

1-10 m (for 5-8 mm diameter)

1-3 m (for 8-12 mm diameter)

Cutting Length Precision: Based on the winding circle

Winding final shape: “8”figure& single tie

Winding distance: 150-250 mm

Tying diameter: 10-40 mm

Production Efficiency: 4 S/PCS (for 2 meter length winding)

Suitable Tying wire: Coated iron core ≤7.5 KG/roll

Operating Air Pressure: 0.6-0.7 MPa

Power Supply: Standard 220V/50Hz

Machine Power: 3.2 KW/H

Machine Dimensions: 1200L x 1100W x 1540H mm

Machine Weight: 260 KG

【Product Advantage】

1,Auto feeding material + auto winding rope into roll & + auto bundling rope roll with bunlding wires in one machine ,

labour saving and high productivity .

2,Precise cutting length &binding up the rope rolls

3,Coiling rope roll diameter , coiling height and coiling length,production speed can be set on the machine based on requirement and also the head and tail ends remaining length can also be set at will .

【Product Details】

1,Feeding ropes , this jute rope coiling bundling machine will feed ropes automatically for winding process ,the rope

goes through inlet and ranking units ,the feeder roller will feed the ropes foward ,maximum feeding rope diameter is

12mm

2 ,Winding system , the clip sicssor performs two tasks, one is to clip rope end to the winding zone ,the other is to

cut rope to length , the rope passes through the ranking unit and will be ranked to different height in winding process.

the distance of the two winding bars determines the rope roll length , the winding bar distance can be adjusted base on rope roll length .

3, Wrapping system, the binding wire will be fed to length on the wrapping hands which will wrap up the rope roll

and the collection hand will take over the wire wrapped rope roll from the wrapping hands .

4,Bundling hands , this PP nylon rope coiling binding machine had been equipped with bundling hands which

allows it to clip and rotate the bundling wires to bind the rope rolls .

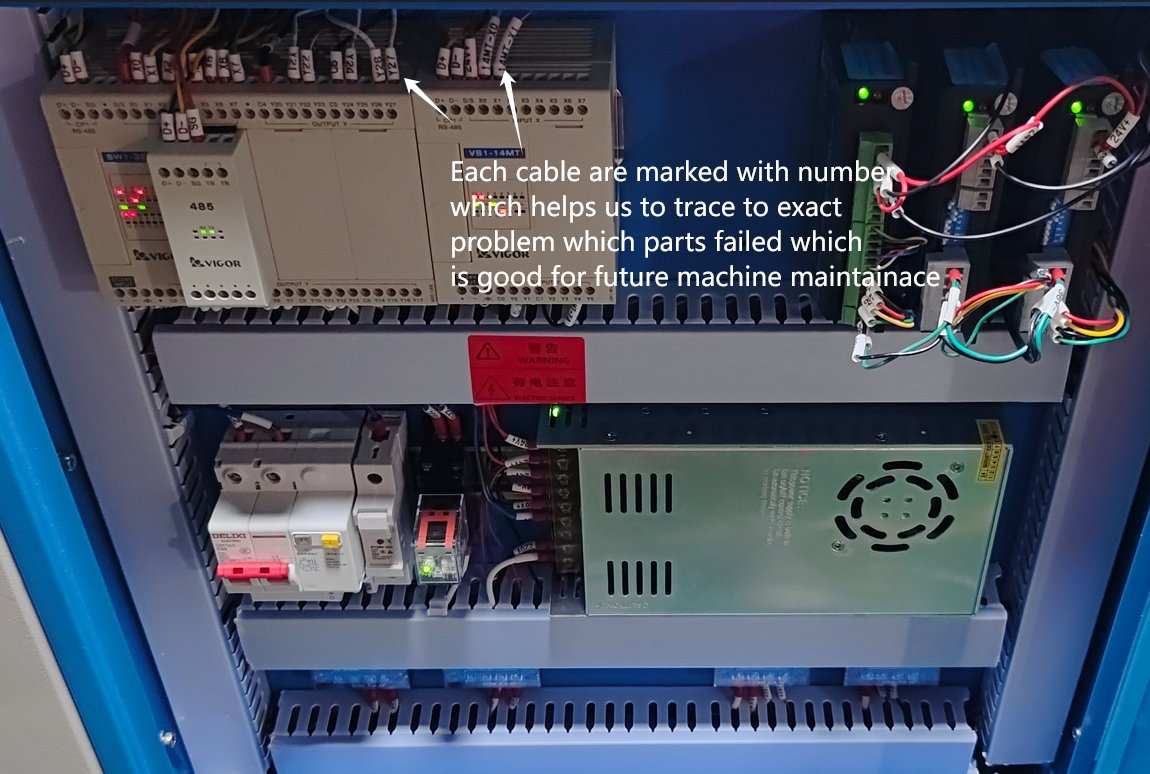

5, Drive with marked connection wires ,every cable is wrapped with a series of number which helps us to trace to

exact problem which sparts failed ,this is good for future machine maintainance .

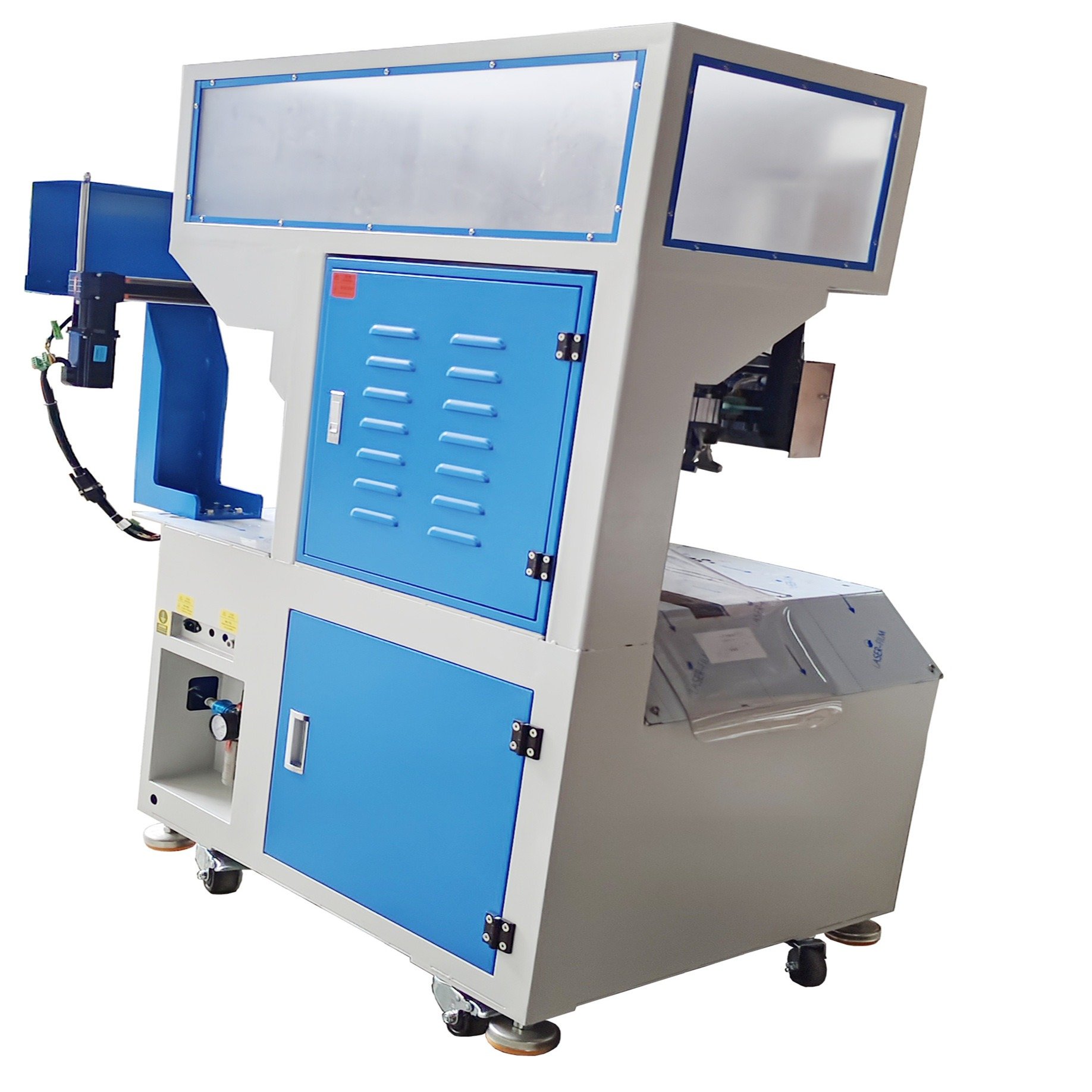

Front View

Side View

Side View

【Warranty 】

As a automatic rope coiling binding machine supplier, all the spare parts of the machine will have one year of free maintainance

by changing the spare parts for free and free shipping of spare parts to overseas clients starting from the issuing date of commercial invoice

after on line diagnosis .

【Packing】

1Set/Wooden case ,foam paddings will be put inside wooden case for safe overseas shipping

Home

Home

Inquiry Now

Inquiry Now Download

Download