2022-07-06 Author : admin

A uk customers named Nick from TYM SEAL&GASKETS LTD in UK who previousely bought the silicone o ring bonding press machine from us which designed for fast bonding of silicone o ring with help of silicone adhesives had requested us to design a relatively smaller lathe cutting machine for them as the what's available on the market giant lathe cutting machines which is very expensive as well .

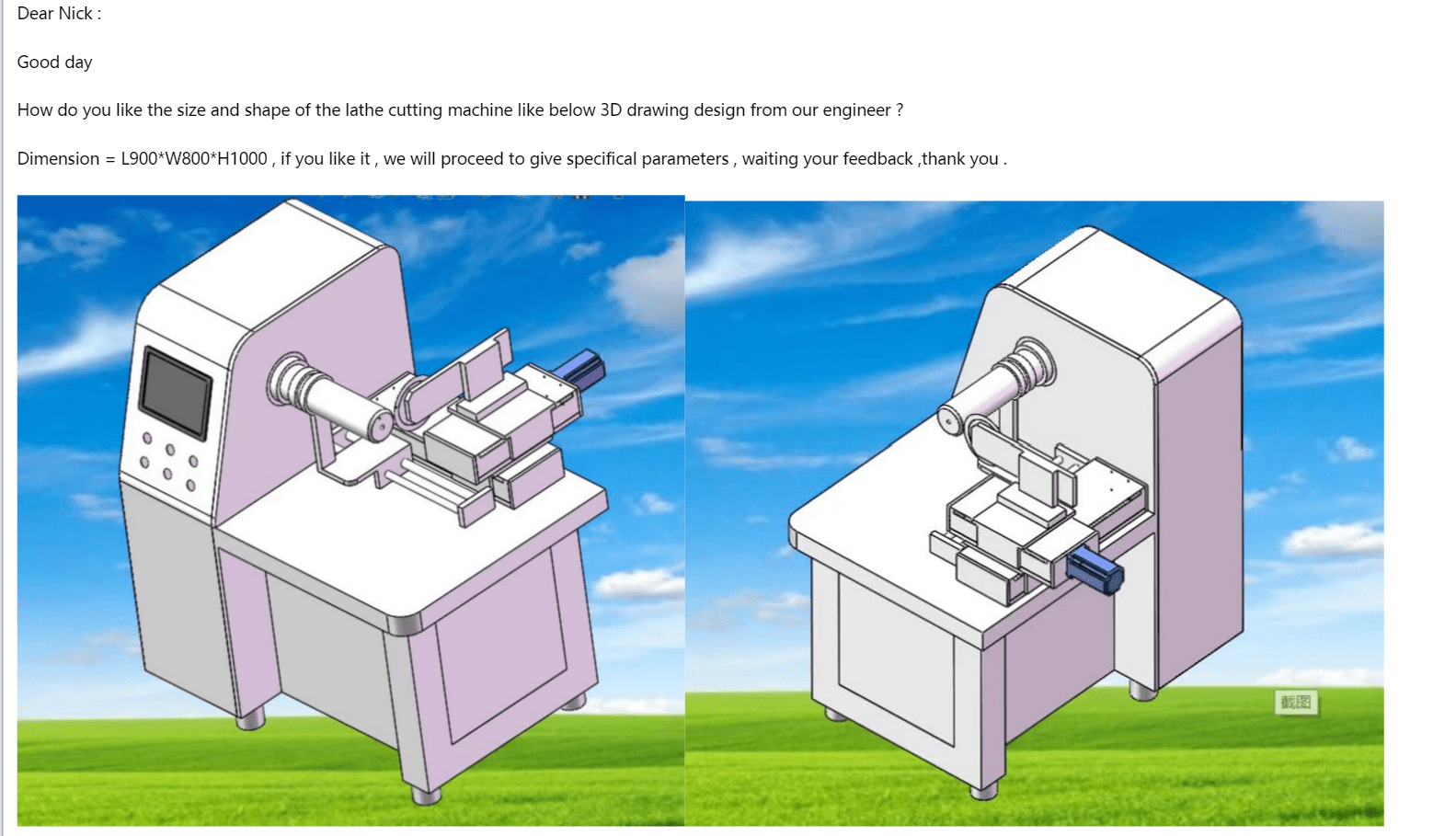

Based on Nick's request ,we have to design the washer lathe cutter machines smaller sizes and also control the budgets for him , from our engineer's perspective , some key components and spare parts which support the auotmation should use the best quality one to ensure the stable working performances of the machine .

Nick 's washer projects is in his regular production and his washer ID is above 15mm , he does not much amounts of washers but request them to be high quality with smooth cutting edges and precision cutting width . so our engineers applies the high speed servo motor on the main axis which supports and holds the washer tube and sleeve and rotate in high speed for the rotation knife to cut it . high speed rotation of main axis and knife is the key to smooth cutting edge requirements and to cut the width precisely will also require the high precision servor motor to control it and high performance lead rail as well .

It takes about one month for our engineers to fully finished making this rubber washer lathe cutting machine , first of all , our engineering team had listened to Nick's request to make this silicone washer precision cutting machine smaller but can serve the same function equivalent to the giant ones in the market and at the same time . we can shrink the costs compared to big ones in the market. we make the washer lathe cutter machine drawings and designs , on nick's approval and order confirmation , we begin make this machine for him , since this is a customised new machine , we have to make molds for the machine structures ,so it take around 30 days to get machine finished production . we test the machine and shoot him working video and processing video how to operate the wash lathe cutting machines , Nick like the machine we customised for him .

Below some key steps progress we made for him the customised washer lathe cutter machines .

Step 1

Discuss with customer their idea and requirement for the cutting machines

(customer requirement)

Step 2

Provide customer with machine design drawing &technical data by our engineer.

Technical data :

Product name : The washer precision cutting machine

Main axis speed : 1440R/min

Cutting diameter: 15mm

Power : 2 phase , 3.0KW

Dimension : L*W*H=900*800*900m

Send quotation to customer and customer confirm the order and pay the order based on PI, we

start production (below customer confirmation)

Step 3

The customised cutting machine will take one month on average to finish production as a lot spare parts will need to make new molds and take time .

When customised cutting machine finishes production , we will test with the cutting machine and send demenstration video ,photos and also shoot clear video how to operate the machine .

Working video :

Operation video :

Customer feedback and confirmation machine ok

On customer approval of the washer lathe cutter machine , we will pack and deliver the machine

As we are a professional customised cutting machine supplier ,if you suffered pain point in your regular production and want to replace labour with automation cutting plus other automation , you can come to us with your requirement and ideas ,we will customise the cutting machines you need to raise your regular production efficiency.