2021-06-01 Author : admin

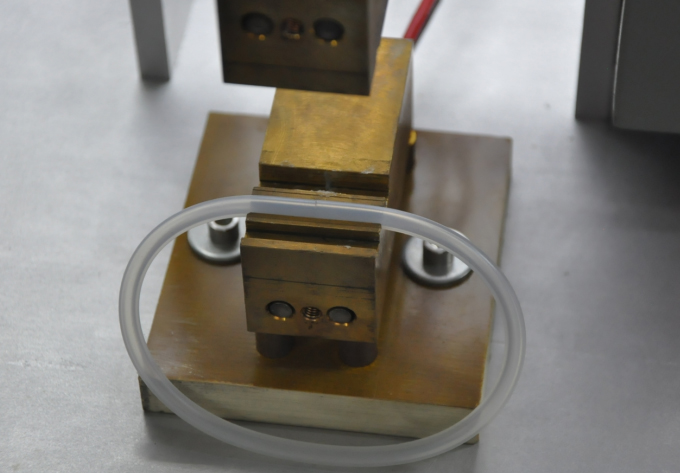

The silicone o ring groove design is an important part to gurantee our silicone o ring gaskets bonding press machine ES-001 can join a cut-to- length extruded silicone into o rings in high productivity, to make silicone o ring groove on the copper mold ,the silicone seals mould cavity design has to follow the principle that the groove sizes have to be similar to the size of silicone gaskets seals to ensure that extruded silicone had tight contact with the copper mold .

That 's also the key to a good bond of silicone to silicone for making silicone o ring gaskets ,we have to make sure the silicone material had full close contact with the mold so the silicone adhesive can be heated to cure fastly in order to create a strong bond of silicone o ring gaskets, so we have to open cavity on the mold precisely which will be according to customers’ size of silicone profiles to form such close contact of your silicone profile with mold .

Regarding silicone seals mould cavity design for silicone tube profiles , we have to open the silicone tube shape on both copper molds will be ok , 1/2 diameter on the down mold , 1/2 diameter on the upper mold .

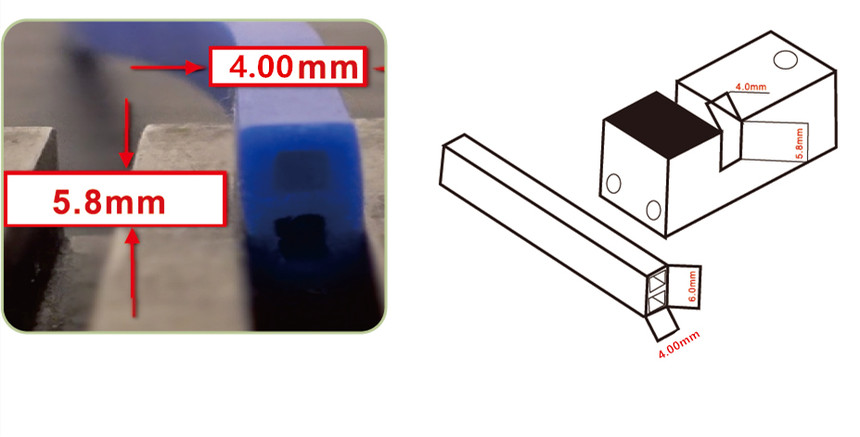

As for silicone gaskets groove design for square and rectangular silicone extruded gaskets ,the cavity is fully created on the down mold and the cavity width can be the same with silicone profile width , but the mold depth should be less than the silicone profile heights , for example , if your silicone profile width is 4.00mm and height is 6.00mm, the cavity width will be same as 4.00mm ,but the cavity depth will be 0.2mm less than 6.00mm , the reasonable cavity depth will be 5.8mm

It is to make sure that extruded silicone can go a little on top of the down mold surface so the upper mold can contact fully with the silicone profiles for a good bond of silicone to silicone ,

We had chosen the pure copper as the mold material as it is of high heat tranfer efficiency to make silicone seals mold cavity , the heat generated by the silicone o ring gaskets bonding press machine ES-001 will not incur loss by the heat tranfer of the copper mold as long as a tight contact is ensured for silicone with the copper mold .

Customer is welcome to send us their size data of silicone profiles. We can customise and design the groove for the regular silicone profile shape for round ,square , rectangle etc , for unregular and complex shapes, customer will have to send us their acutal silicone profile sample so we can design the groove on the copper mold more precisely. Above is silicone o ring groove design

Our silicone o ring gaskets bonding press machine ES-001 is designed for joining silicone o ring gaskets /profiles fastly to boost the production of silicone extrusions manufacturers . you can contact michael at sales@cnesmai.com for details .