2024-12-23 Author : admin

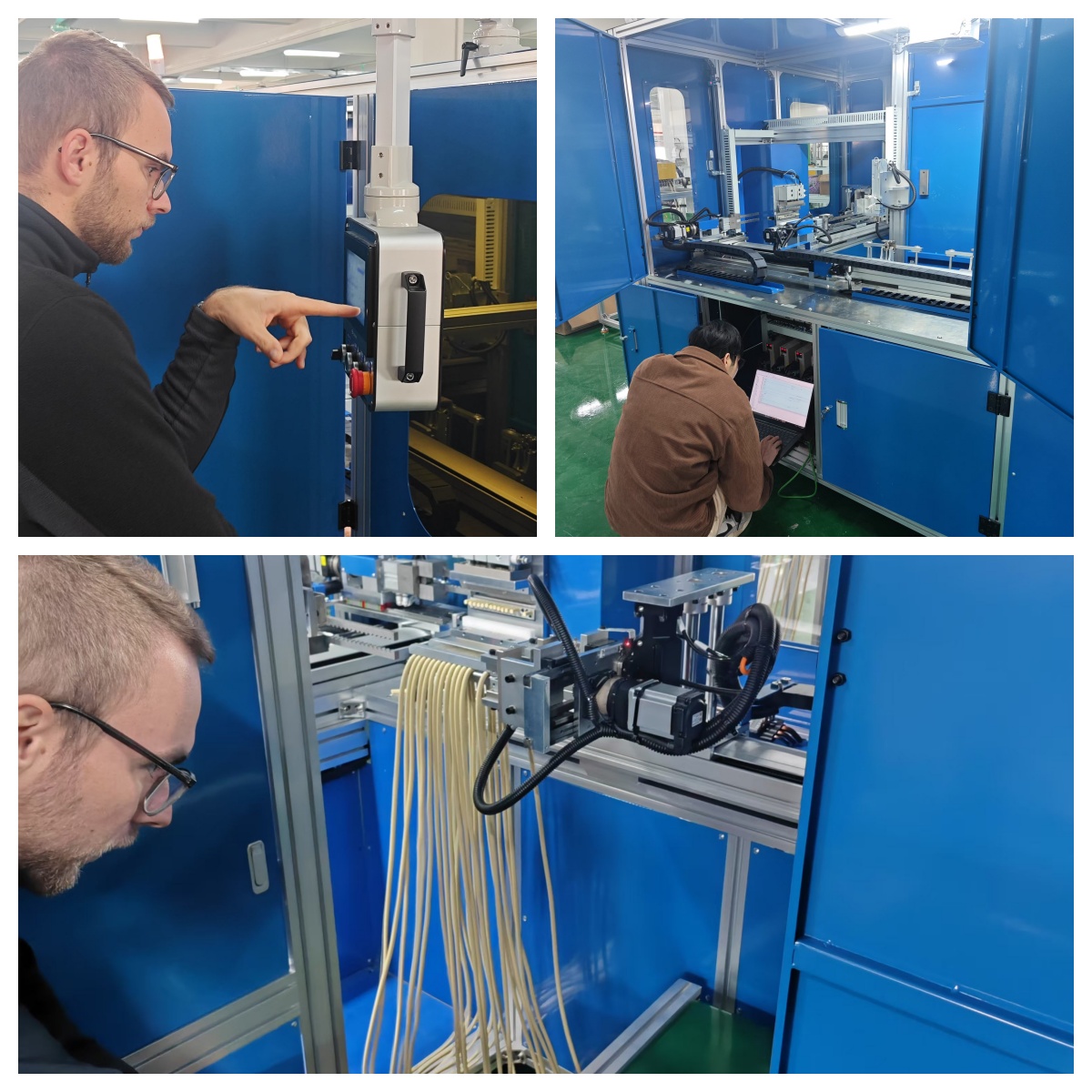

One of our customers from germany placed an order with us for the sponge rubber oring fully automatic cutting and bonding machine ES-060-1 ,but they request to add quality inspecting function on the machine to save manual labour to inspect the joint quality of rubber orings , below is the working video how the rubber oring fully automatic cutting and bonding machine works with an inspection device .

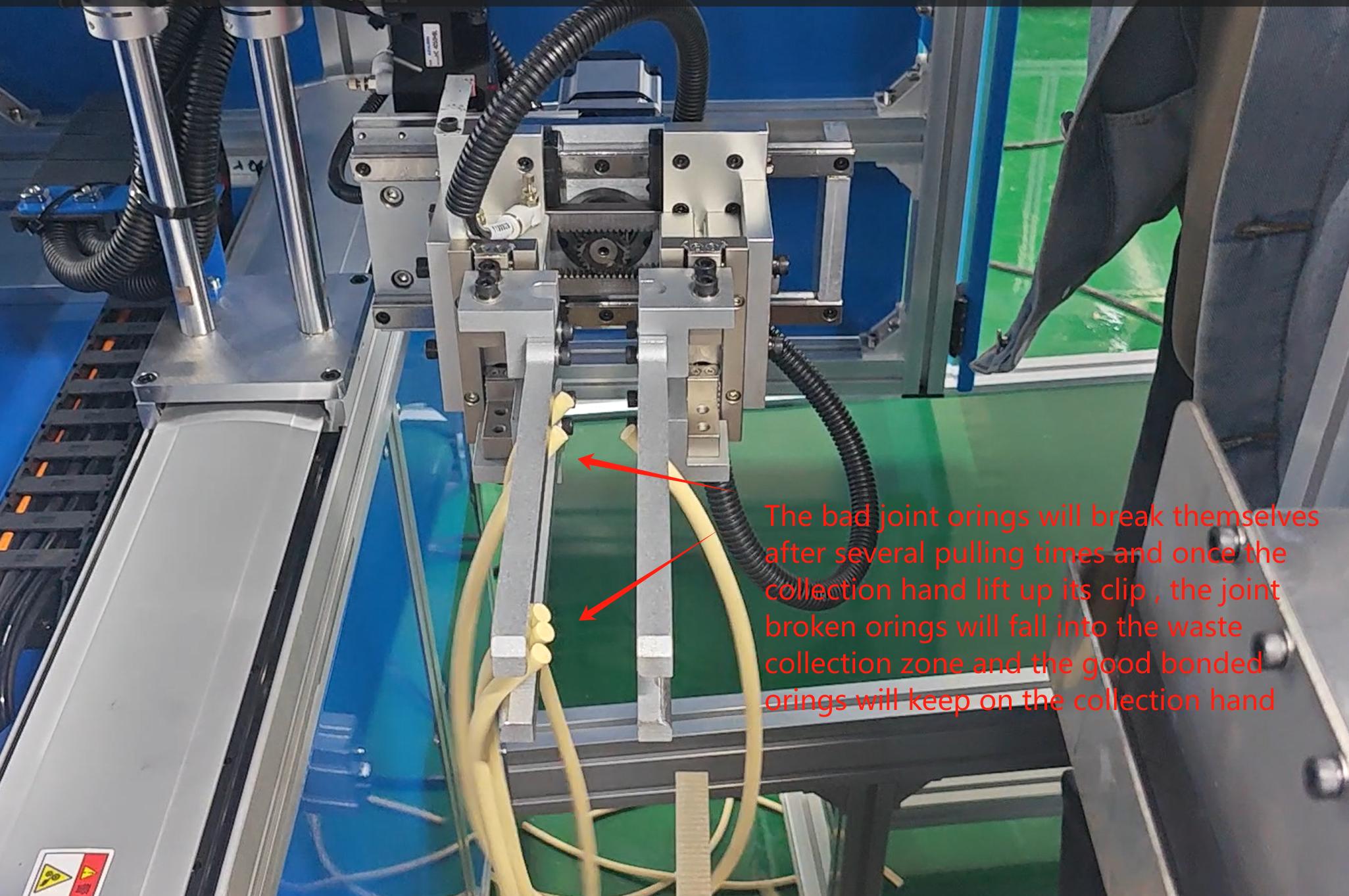

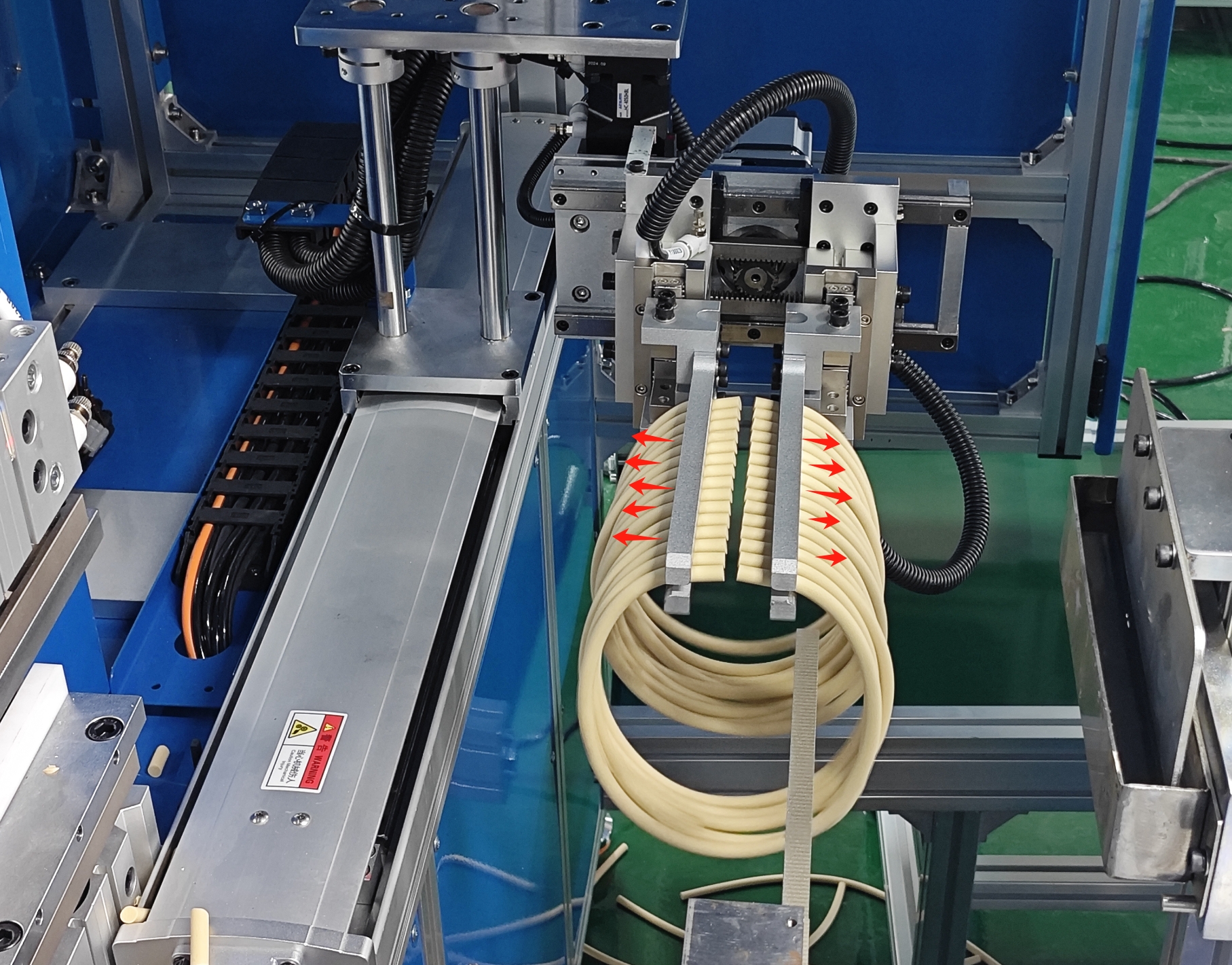

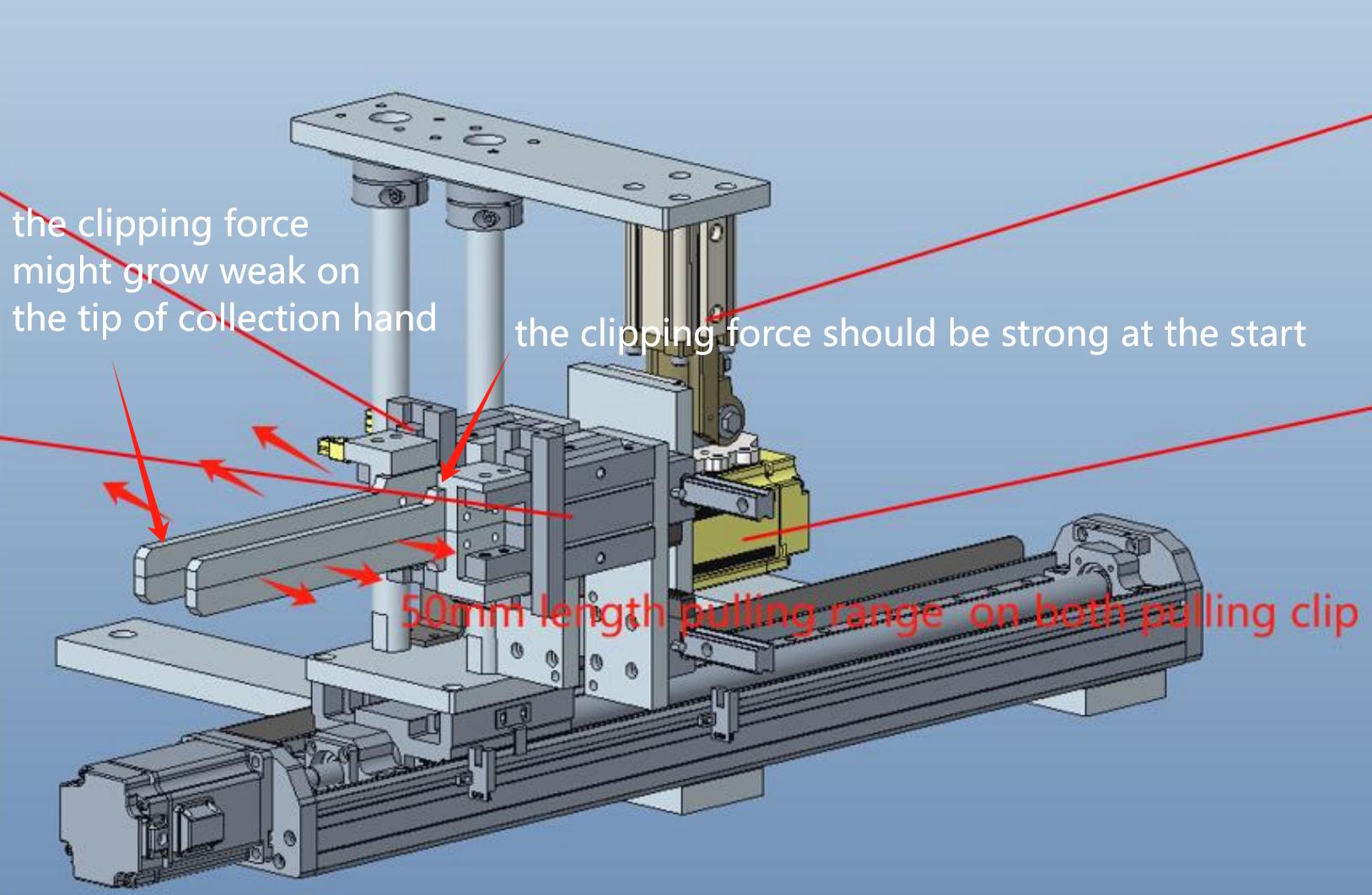

In difference to the standard rubber oring fully automatic cutting and bonding machine ES-060-1, this sponge rubber oring quality checking machine ES-060-1 had a collection hand which can pull on both reverse directions to break off the bad joint orings .

the bad joint orings will break themselves after several pulling times and once collection hand lift up its clip , the joint broken orings will fall off the collection hand into the waste collection zone .

The good joint orings will be fowarded to the transport conveyor belt bands and get into the collection box for collection .

It is following this method that we manage to separate the bad joint oring from the good ones by our rubber oring joint quality inspecting machine ES-060-1, because the bad joint orings will fail the pulling test done by the collection hand and break themself on the weak joint and fall off the collection hand into waste zone , the good joint orings will keep the collection hand and be selected as good ones .

Based on different hardness and different diameter of sponge rubber orings , we can increase the pulling times of collection hand ,like pulling 3 or 5times and pulling distance to be 30mm or 50mm on both direction can be set , when it reaches maximum pulling distance , we can set the hold pulling times, like you can set 3seconds or 5 seconds hold pulling times when the pulling reaches maximum pulling tension distance ,in this tension condition , the bad joint orings will break on the weak joint .

Our imaginary concern for this rubber oring automatic manufaturing machine is that the collection hand will have strong clipping force at the start part and the clipping force will grow weak on the tip of the collection hand , if the clipping force grows weak on the tip of the collection hand , the weak joint orings will slip during pulling test and will not break on the joint , in this case ,we still can not manage to do the pulling test well and select bad joint orings from the good ones

By using the maximum size air cylinder of strong power for this O-ring fully automatic vulcanization machine ,this problem is conquered and didn’t show up during our test with different size and hardness rubber orings .

Instead , the problem was another one that came to us , some of the broken joint orings didn’t fall off the collection hand , because the height of the upper collection hand blocked the tip of broken orings from falling off collection hand , in this case ,it is still on the collection hand with good joint orings and will still need to select them out manually .

By lifting up the travel range and height upper collection hand about 12mm more height , this problem disappear and the broken joint orings can fall off of the collection hand easily without the block of the upper collection hand .above is details how to automatically inspect joint quality of sponge rubber oring gaskets.

Thanks to the good and practical idea of our german customer , with their strong sense of detection and brilliant idea and continous and best effort our engineer , we managed to upgrade our rubber oring fully automatic cutting and bonding machine ES-060-1 with quality inspection function in simplified and practical way . it saves manual labour to select bad joint orings from good ones and lives up to production requirement of silicone or rubber oring manufacturers with strict requirement of quality of silicone or rubber orings production .