.

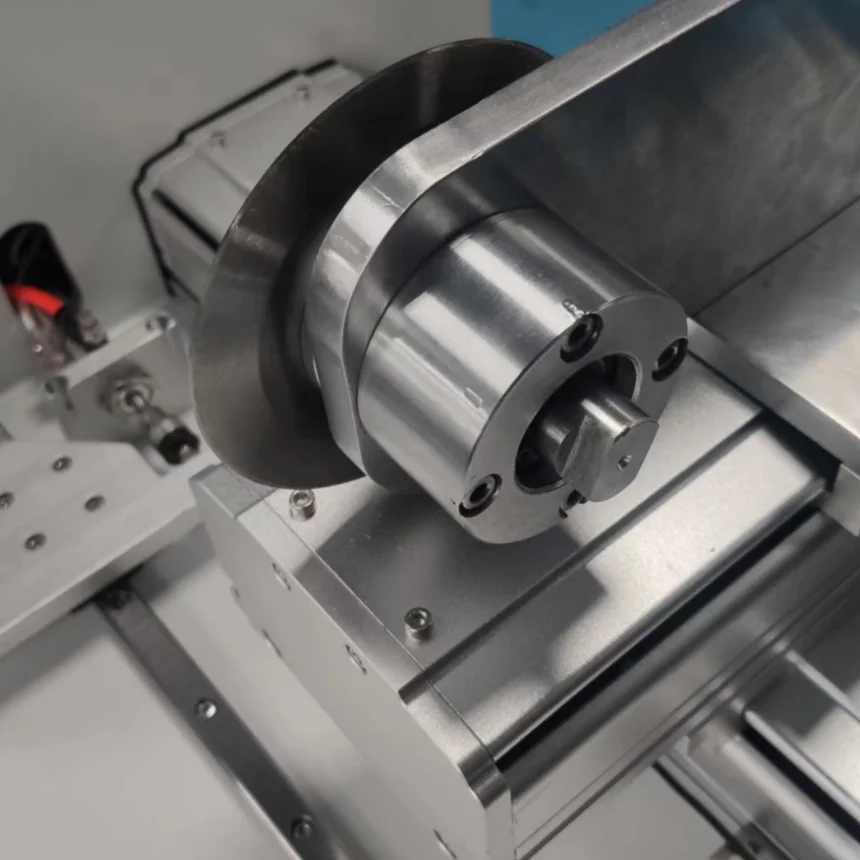

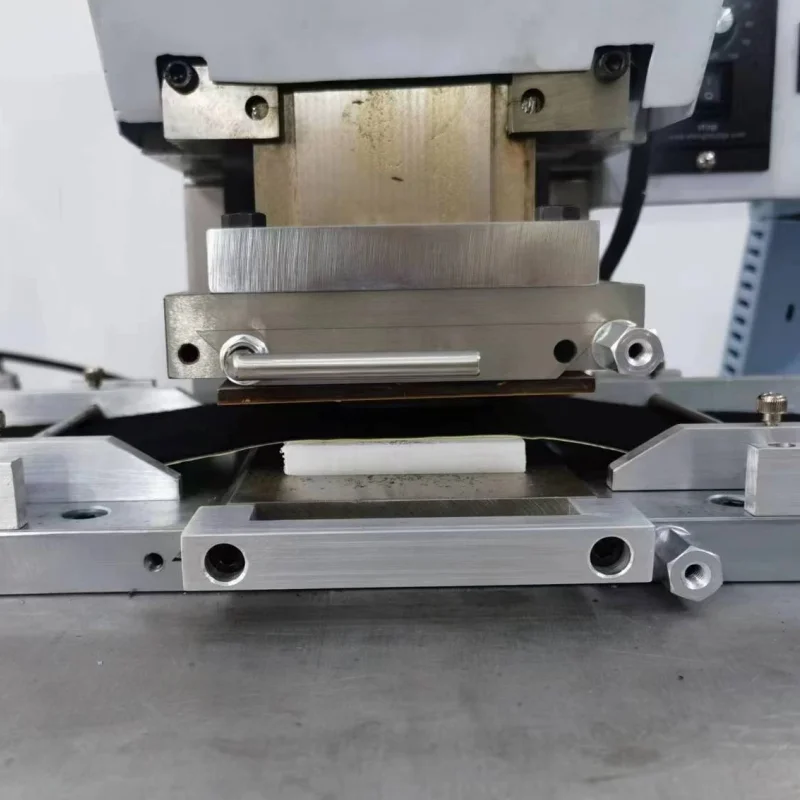

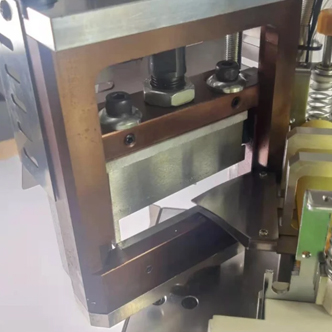

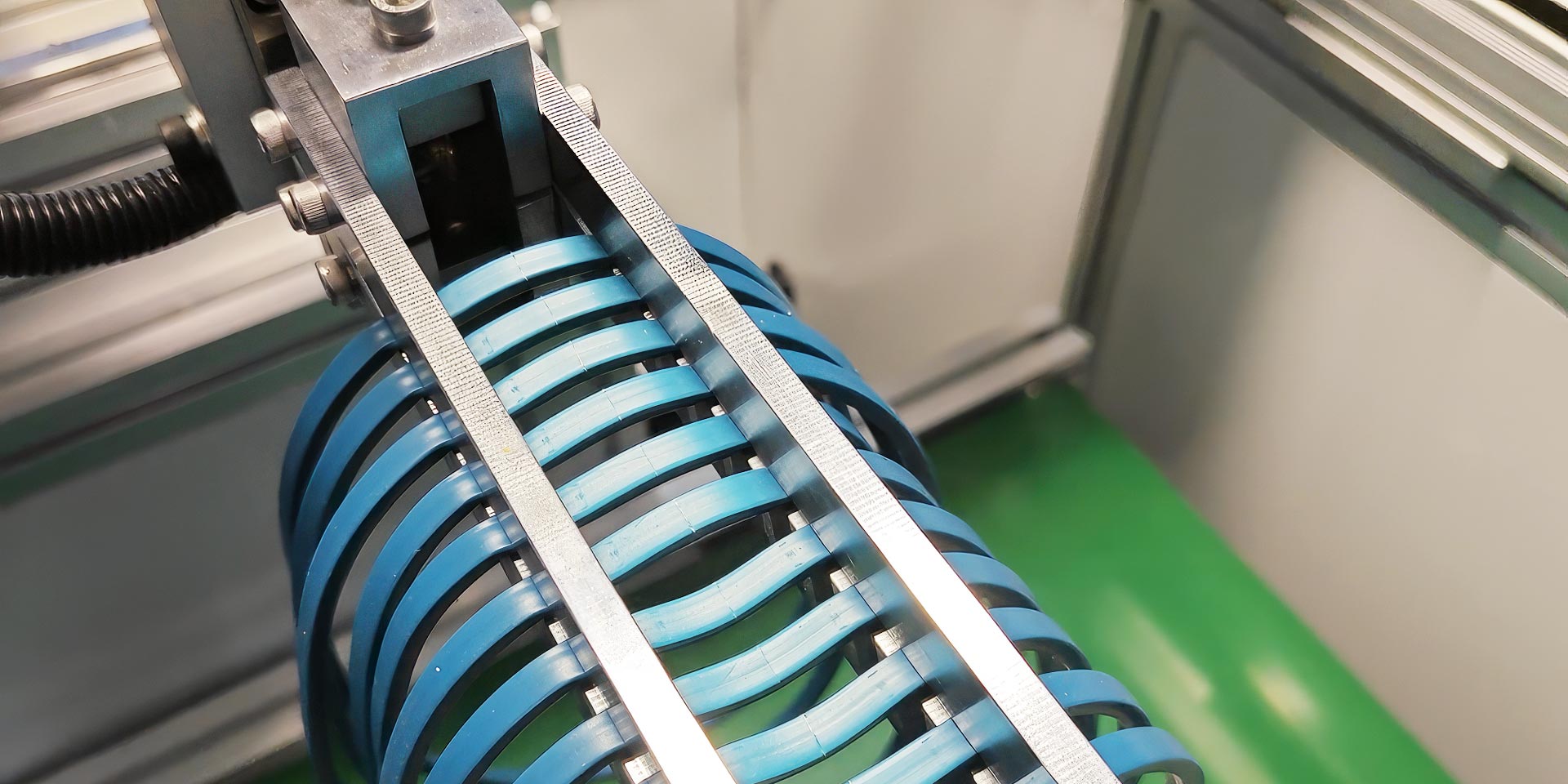

ESMAI is a manufacturer that specializes in custom-made cutting machines. The customized cutting machines adds other automated processes on the basis of cutting replacing all the processing steps of customers’ manual production of their products with automated processes helping customers save labor and improve production efficiency.

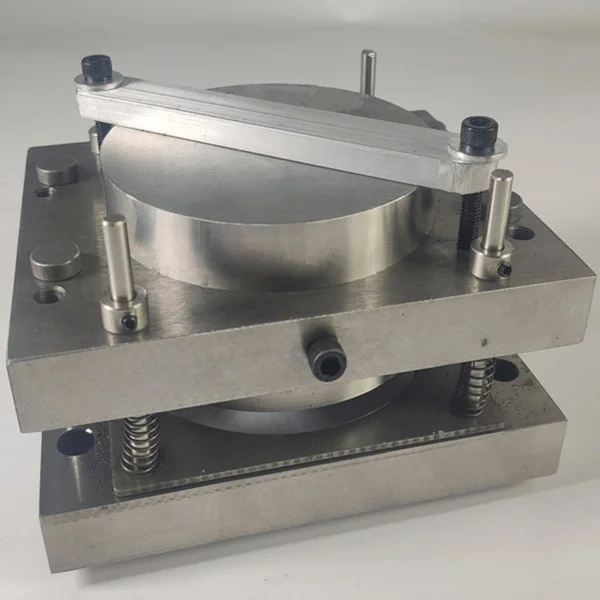

Our customised cutting machines applies for cutting and processing silicone and rubber oring gaskets silicone tubing&cord&sponges adhesive silicone strips and narrow fabrics like webbing elastics velcro tapes ropes leather and fabric sheets and auxilary machines like silicone o ring gaskets joining vulcanizer press machine etc.