Foam rubber O-ring fully auomatic cutting and bonding machine with joint quality inspection device ES-060-1

The foam rubber O-ring fully auomatic cutting and bonding machine with material inspection device is designed for automatic cutting and bonding extruded foam rubber gaskets into orings with joint quality inspection function which the bad and weak joint O-rings will be cleared out and good joint O-rings will be collected which saves manual labour to inspect joint quality . In the meantime , the actual cutting length will be same as the setting length by calculating the length compensation value for each type gaskets , 20 such calculation formula can be stored and retrieved with one click of touch screen which is conveninent to use .

This machine can process 15 pieces of sponge rubber material simultaneously, achieving a high production volume of 20,000 to 36,000 pieces per day, based on a cutting length of 350-550mm and a 10-hour workday.

This rubber O-ring splicing and vulcanizing machine also had material lacking alarm , the machine will show yellow light and sound alarm when any of the 15 pcs gaskets runs out of material to remind workers to load or splice on new gaskets material .

The machine is available in three models based on cutting length: 1 meter cut length type, 1.5 meter cut length type and 2 meters cut length type , Customers can select the appropriate model according to the maximum cutting length required for their sponge or rubber gasket materials.

The foam rubber gaskets cutting and joining machine supports a minimum cutting length of 200mm( can be customised to 190mm if needed ) and a processing diameter range of 1-8mm. For diameters between 8-12mm or even bigger diameters, customers can equip the machine with an additional enlarged feeder. With this setup, up to 8-10 pieces can be processed simultaneously for larger diameter sizes

Youtube video

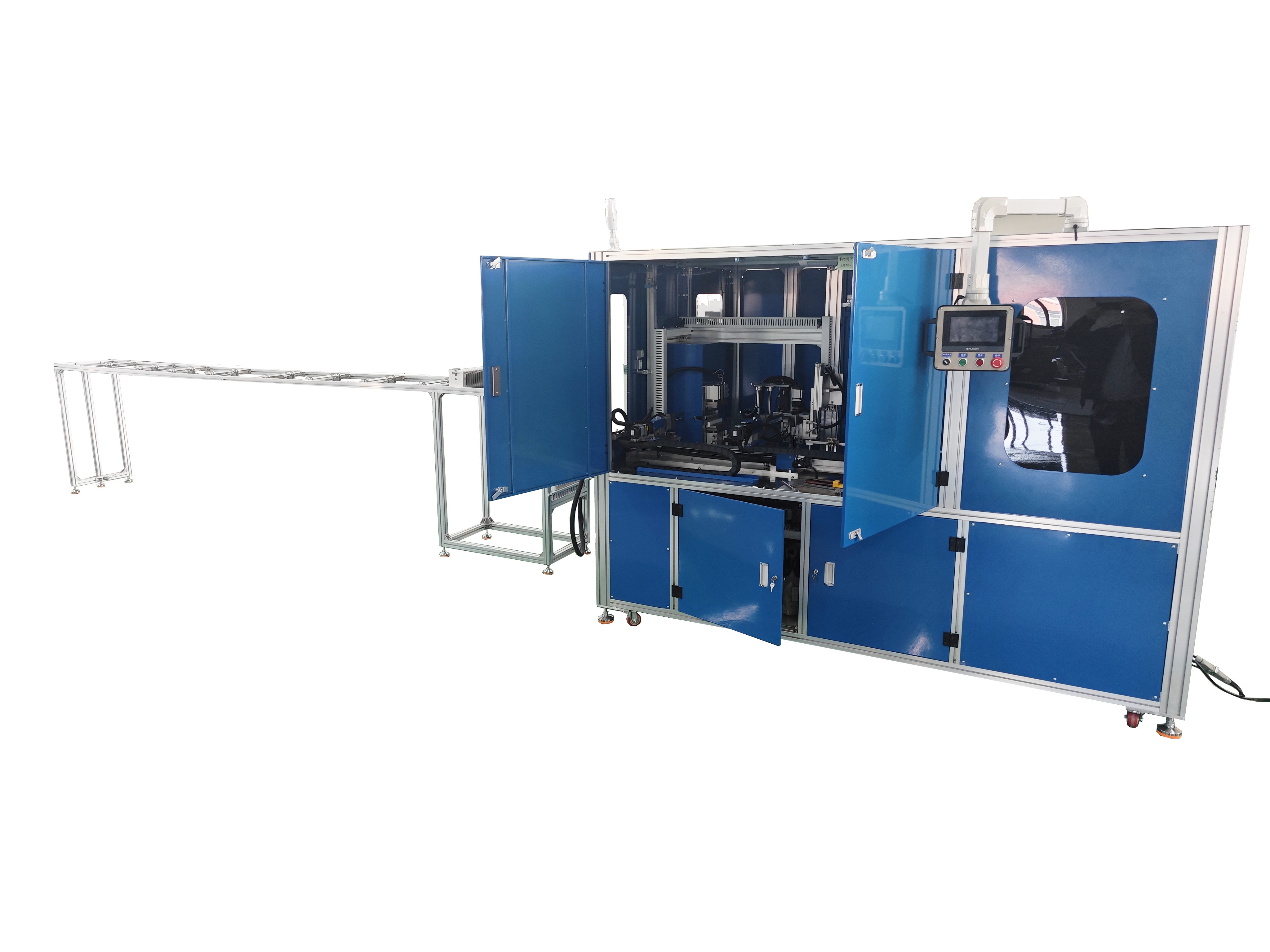

Full safety cover is applied on this machine with only pvc transparent window to look inside and once the safety door opens during machine working process , the machine will sound alarm to elevate safety precautions .since the machine applies with full enclosed safety doors, A instant glue sucker fan is installed on top of the machine to reduces glue odor with a 10-minute work cycle followed by a 1-minute fan working to suck out the odor of glue from inside the machine .

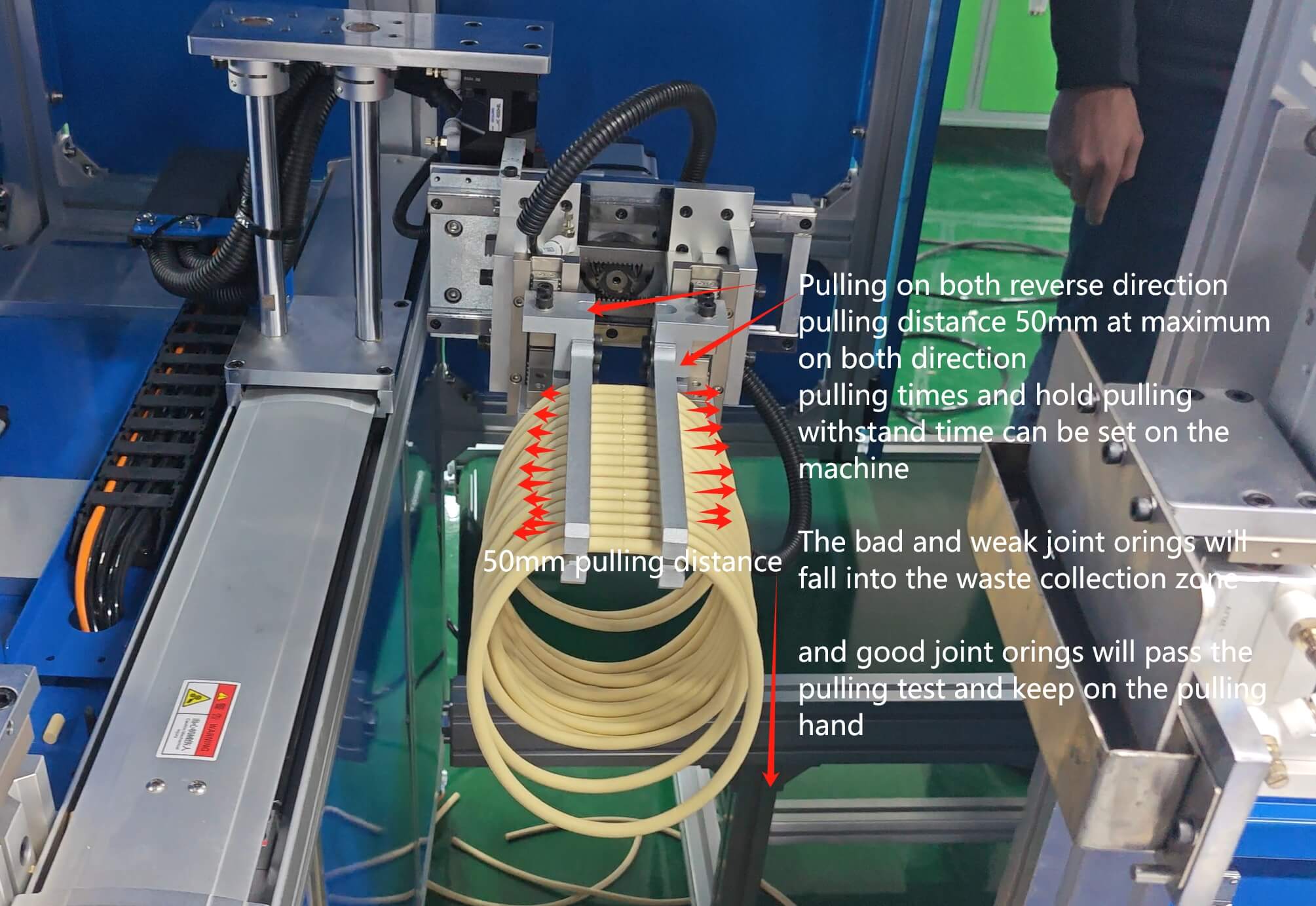

The advantage of this foam rubber fully automatic cutting and bonding machine is that it had installed with joint quality inspection device which the collection hand itself serves pulling test to break the bad joint orings with streching on the joint and hold streching tension time , the breaked joint orings will fall off the collection hand and cleared away . this function saves labour to do quality inspection and which meet with high quality requirement of silicone extrusion customers .

【Technical Data】

Product name: Foam rubber O-ring fully auomatic cutting and bonding machine with joint quality inspection device

Function: Automatic feeding + fixed-length cutting + glue dipping + bonding into O-rings + material inspection and collection & clear out bad joint orings

Bonding method: The clipping hands fixes the connection position +502 glue or other cyanoacrylate glue gets cured to bond the sponge rubber gasket into an O-ring.

Details of the material inspection device: The material inspection and holding stretching time & stretching length & stretching times can all be set

Formula selection: 20 parameter receipt can be stored and retrieved at will & the length compensation value is calculated

by the arranged formula and can be imported on the touch screen.

Glue sucker fan : exhaust to dilute the smell of glue in the machine, work for 10 minutes and exhaust for 1 minute.

Alarm system: lack of material alarm, yellow light flashing to remind workers to load new material.

Machine safety cover: fully enclosed safety cover with PVC transparent window & open the safety cover, the machine raise alarm.

Machine power: 5KW

Machine power: 220V/110V

Machine capacity: 15 pieces can be processed at a time (gaskets diameter 1-8mm, for bigger diameter 8-12mm,

it needs apply with enlarged feeder which 8-10 pieces can be processed at the same time)

Air pressure: 0.6-0.8mp

Control system: PLC touch screen (Touchwin)

Maximum cutting length: 1m, 1.5m and 2m according to the machine model

Minimum cutting length: 200mm (can customized to 190mm)

Processing diameter: 1-8mmOD (8 mm or more, for bigger diameter 12mm or above, with enlarged feeder)

Cutting length accuracy: 500mm±2, 1000mm±3

Main components: servo motor (Hechuan, domestic first-class brand), cylinder (AIRTAC), PLC (TouchWin),

other electrical components (Omron, domestic first-class brand)

Machine capacity: 20000-36000 pieces/day (calculated based on 10 hours per day)

Machine net weight: 700KG

Machine size: L 2150mm*W1950mm*H1950mm

Feeder size: L5000mm*W800mm*H1500mm

【Product Advantage】

1, Inspect the joint quality of bonded O-ring gaskets automatically and saves labour inspection , the bad or weak joint O-rings will be fail the pulling test with severy times of pulling and withstand pulling time and longer distance pulling elongation and fall off the collection hand into waste collection zone and the good joint orings stays on the collection hand and be fowarded to conveyor belt for final collection .

2, 20 receipes formula to be stored , the actual cutting length will be same as setting length with a formula set up and input in the machine by in -house engineer from customers

3, High production volumme of 2000-36000pcs of bonded spone rubber gaskets (taking 350-500mm cutting length and 10 hour a day as example) with 15pcs of sponge or rubber tube cord gaskets to be processed at the same time & good joint quality & strong bonding strength .

【Product Details】

1 Joint quality inspection device , the collection hand will serve joint quality inspection device which the collection clip hands will

pull two gaskets ends on reverse direction with pulling distance 50mm at maximum

The pulling material elongation distance ,pulling material widthstand time and pulling material times can all be set on the touch screen

the bad and weak joint orings will break themself on the joint and fall into the waste collection zone and good joint orings will keep on the

collection hand and moves to the conveyor belt band for collection purpose , this joint quality inspection device will clear out bad joint orings

and separate from good ones which saves the labour to do qualiy inspection .

2,Outside PLC touch screen & Length compensation formula , this foam rubber cords cutting and bonding machine applies with

outside PLC touch screen which is more safe and convenient for workers to operate the machine outside the machine body

Usually the actual cutting length had some difference from setting length and we will have to make up the length compensation manually

now this machine had been equipped with length compensation value formula which the engineer can work out the formula themselves for specical gasket,

so after you set the cutting length on the touch screen , the actual cutting length will come out same as the cutting length .

3, Safety door protection , this rubber oring fully automatic manufacturing machine applies with full safety door cover with only

the transparent PVC window to look inside

the safety door had been equipped with sensors , when the safety door opens ,it trigger the alarm and the machine will stop working

automatically for safety protection of workers purpose .

4, Instant glue sucker fan ,this foam rubber oring autommatic cutting and bonding machine had equipped with a sucker fan on top of the machine to suck up

and dilute the concentration of instant glue smell in the enclosed machine with full safety cover . the fan will suck up instant glue for one minute and rest for

10 minutes .

5, The two mechanical clip hands are responsible for drawing the rubber gaskets material to fixed cutting length

,dipping gaskets with glue and join rubber gaskets ends ,let the glue to cure and form a strong bonded orings

The cutting knife will cut off the gaskets after the length of 15pcs gaskes are drew .

6, Middle supporter , this sponge rubber O-ring cutting and jointing machine had been equipped with middle supporter ,the middle

supporter will raise up after length of gaskets passing through them to support the gaskets weight from pulling down which can avoid

the big cutting length tolerannce .

7, Glue container ,the glue container holds the instant glue , the dipping boards will dip down into the glue container after the gaskets

are dipping glue from it . the glue will naturally flow down to a thin thickness for good control of glue amount distribution on the joint .

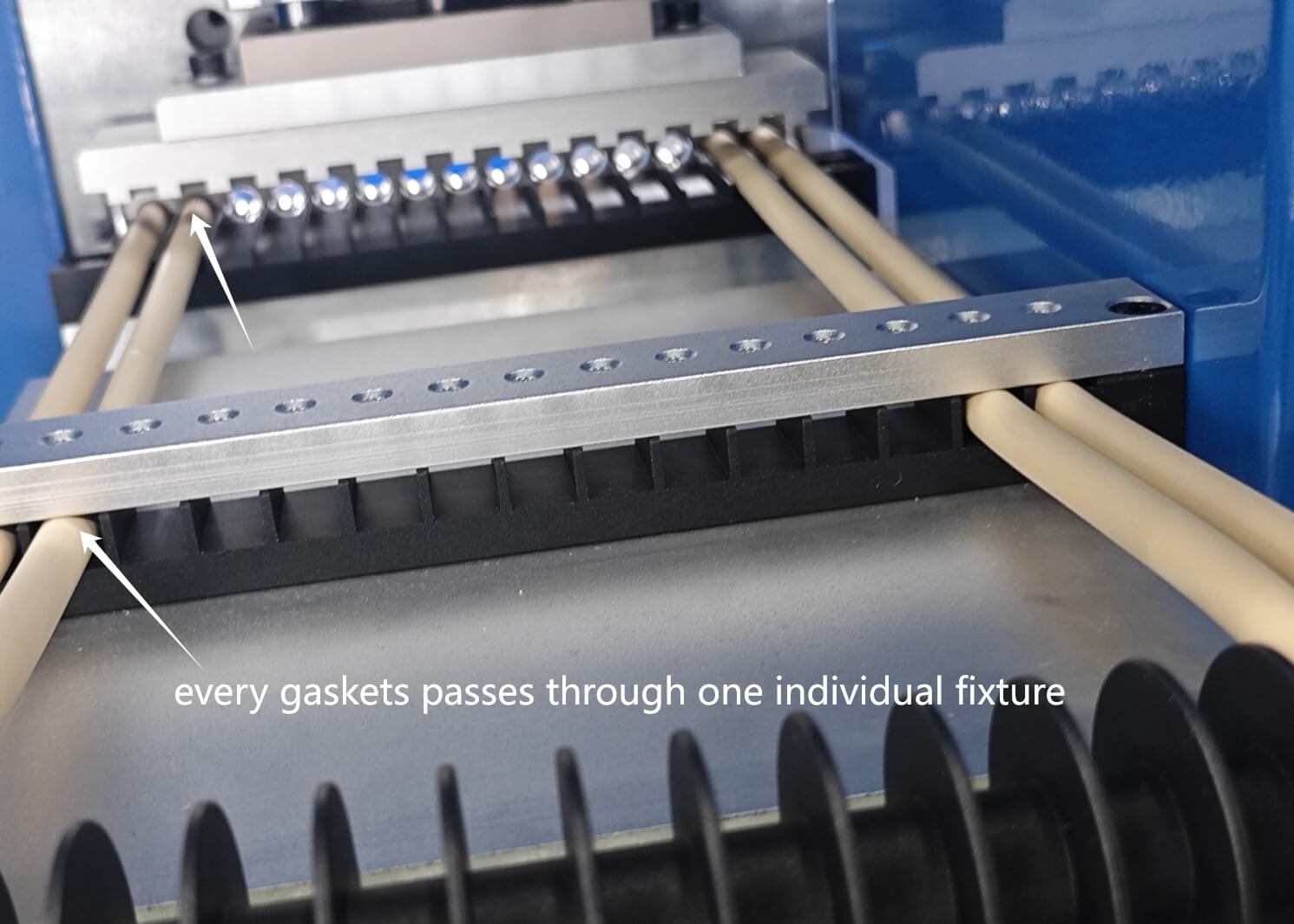

8, Feeder part , the feeding device plays an important role for the machine , every pc foam sponge rubber gasket passes through

one individual fixture and is fed by indidvidual feeding wheels

Every foam rubber gasket passes under one sensor wheel , when they are pulled , the sensor wheel will be lifted up away from the sensor

under the wheels and the sensor will signal the feeding wheels to feed gaskets forward .

9,Collection of the bonded foam rubber O-rings , the processed O-rings are dropped onto the transport conveyor belt, which carries

them to the collection box below. This system saves the need for manual collection, saving labor and improving efficiency.

Front View

Side View

Back View

【Warranty 】

As a foam rubber O-ring fully auomatic cutting and bonding machine with joint quality inspection device supplier , all the spare parts of the ES-060-1 machine will have one year of free maintainance by changing the spare parts for free and free shipping of spare parts to overseas clients starting from the issuing date of commercial invoice after on line diagnosis .

【Packing】

1Set/Wooden case ,foam paddings will be put inside wooden case for safe overseas shipping ,G.W after packing wooden case is 1T, Wooden case dimension is (L2850+W2150+H2150MM)

Home

Home

Inquiry Now

Inquiry Now Download

Download