Sponge rubber oring automatic cutting and bonding machine ES-060-1

The sponge rubber oring automatic cutting and bonding machine is designed for automatically cutting and bonding sponge rubber tube cords ,profiles into oring gaskets . It involves automatic feeding spone rubber gaskets , drawing gaskets to fixed cutting length and cut off the length , dip gaskets ends with instant glue like 502 glue and join the dipped glue gaskets let glue to cure and form a strong bonding , this foam sponge rubber oring automatic bonding machine combines all above processings in one machine which saves labour to do them manually .

15 pcs of sponge rubber material can be processed at the same time on the machine with high production volumme of 20000- 36000pcs per day (based on cutting length 350-550mm and 10 hour a day)

The minimum cutting length is 200mm , the processing diameter is ranges 1-8mm , if customer process 8-12mm diameters , they can equip with one extra enlarged feeder will be ok and for processing big diameters sizes , 10 pcs can be processed at one time .

Youtube video

This silicone tube automatic welding press machine applies PLC touch screen controls which is easy to operate , the silicone cords automatic joining press machine is 5kw power and the motor is servo motor from brand HCFA and the pnematics from brand AirTAC in taiwan and the machine is also equipped with complete alarm system ,every alarm will have code and by knowing the code ,we can trace directly to the problem and solve the problem in fast manner which is good and smooth for after sale service .

Customer can set the unit cutting length of silicone o ring gaskets on this silicone o ring automatic fusing machine , adhesive intake amount ,adhesive brushing times , gaskets dipping adhesive times based on the sizes silicone gasket , heat time and heat temperature etc.

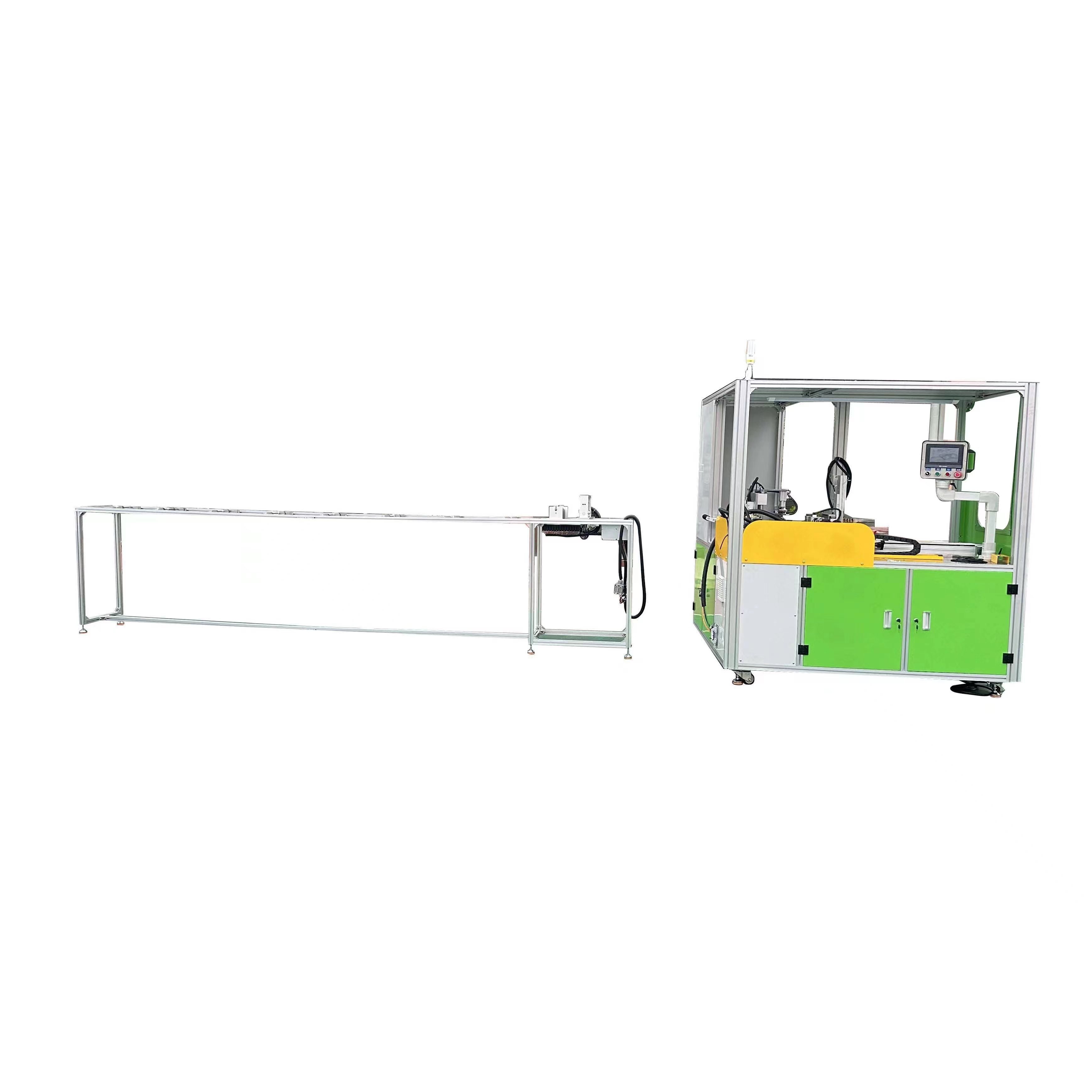

The machine is made of feeder part and cutting and bonding machine part , the feeder part had been equiped with fixtures and sensor , every gaskets had to go through an individual fixture and sensor , the sensor will sense any pulling from beneath and sign the feeder motor to feed in more silicone gaskets and avoids tangles and knots , smooth feeding process. the feeder part is important and key for smooth processing of mult silicone o ring gaskets .

The bonded silicone orings are with good and stable bonding strength ,zero failure bonding rate , the joint quality is nice with little adhesive residue on the joint by making the mold cavity based on the gaskets precisely and bonding strength is also strong , the cutting length tolerance is small by the mechanical hands to draw the cutting length accurately . great productivity and labour cost are saved by this Silicone tube cords o ring cutting and bonding machine .

【Technical Data】

Product name : Sponge rubber oring gaskets cutting and bonding machine

Model No.: ES-060-1

Function : Auto feeding material +cutting to length+dipping glue +bonding into orings

Bonding method: Mechanical hands fix joining position +502glue or other cyanoacrylate glue cure to bond sponge rubber gaskets into orings

Machine power: 4KW

Machine capability : allowing 15 pcs to be processed at one time (for tube cords diameter 1-8mm ,8-12mm OD with enlarged feeder with 10pcs to be processed )

Air pressure : 0.6-0.8mp

Control system : PLC touch screen

Mininum cutting length : 200mm

Proessing diameter : 1-8mmOD (Above8 mm and less than12mm OD with enlarged feeder)

Cutting length tolerance:500mm±2,1000mm±3

Main component : Servo motor(Hechuan ,Top brand in China),Air cylinder(AIRTAC),PLC(TouchWin),Other electrical comonents( OMRON, Top brands in China)

Machine productivity:20000-36000 pcs/day(based on 10 hours a day)

Machine net weight: 0.5T

Machine size: L1750mm*W1650mm*H1950mm

Feeder size:L5000mm*W800mm*H1500mm

【Product Advantage】

1,Precise cutting length with little cutting length tolerance , the joint quality is nice without dislocation and little adhesive residue ,bonding strength above 5kg

2, Auto feeding sponge rubber cords +draw rubber gaskets to length +cut off the length + dipping one end gaskets with 502 glue + join glue dipped

gaskets ends to form a strong bond in one machine which is fully automatic and labour saving to do all process manually .

3, High production volumme of 2000-36000pcs of bonded spone rubber gaskets (taking 350-500mm cutting length and 10 hour a day as example) with 15pcs of sponge or rubber tube cord gaskets to be processed at the same time .

【Product Details】

1,Feeder shelf with multi fixtures ,every pc rubber gaskets passes one individual fixture allowing

15pcs sponge rubber gaskets for processing by the rubber oring gaskets automatic splicing machine

2,Feeding roller&sensor wheels , this foam rubber cords cutting and bonding machine applies 15 feeding

rollers ,each roller roll and feed one pc gasket.

Eevery pc songe rubber gaskets passes under the sensor wheels , when the sensor wheels are lifted

the feeding rollers will roll and feed gaskets ,then the sensor wheels go down and touch the sensor

under it ,the sensor will signal the feeding roller to stop feeding and the gaskets will be pulled up

from the sensors and start to feed again .

Multi fixtures to hold the rubber material in straight and parrell line for processing .

3,Cutting knife, after the cutting length of rubber gaskets are drew , the cutting knife will drop down

to cut off the rubber gaskets and the cushion board beneath will lift up to support knife for cutting .

4, The two mechanical hands are responsible for drawing the rubber gaskets material to fixed cutting length

,dipping gaskets with glue and join rubber gaskets ends ,let the glue to cure and form a strong bonded orings

5, Glue dipping boards &container, the glue container holds the 502 glue or other cyanoacrylate instant

glues the glue dipping boards will dip down to the contain with the glue after the gaskets material dip glue

from it to ensure rubber gaskets alway had sufficient glue to dip from the glue dipping boards . the glue container

can preserve the glue for one day in liquid form .

6, Collection hands ,the collection hands will take bonded orings from the mechanical hands

the bonded orings joints are in one alignment ,good for checking the bonding quality

7, Over view , All below working components working together for drawing sponge rubber gaskets to length

cut it off ,dipping rubber gaskets ends with glue and join them for bonding into oring gaskets

8 , PLC touch screen, the sponge rubber oring automatic joining machine applies with PLC touch screen

which is easy to operate the machine ,customer can set product prameters, exact cutting length , bonding speed

,total quantity .etc .

9,Collection of the bonded silicone o rings , the processed o rings will be dropped to the transport

bands ,the transport bands will transport the finished orings into the collection box beneath it which saves

labour to collect finished orings

Front View

Side View

Side View

Back View

【Warranty 】

As a sponge rubber oring automatic cutting and bonding machine supplier , all the spare parts of the ES-060-1 machine will have one year of free maintainance

by changing the spare parts for free and free shipping of spare parts to overseas clients starting from the issuing date of commercial invoice after on line diagnosis .

【Packing】

1Set/Wooden case ,foam paddings will be put inside wooden case for safe overseas shipping ,G.W after packing wooden case is 1T, Wooden case dimension is (L3050+W2150+H2150MM)

Home

Home

Inquiry Now

Inquiry Now Download

Download