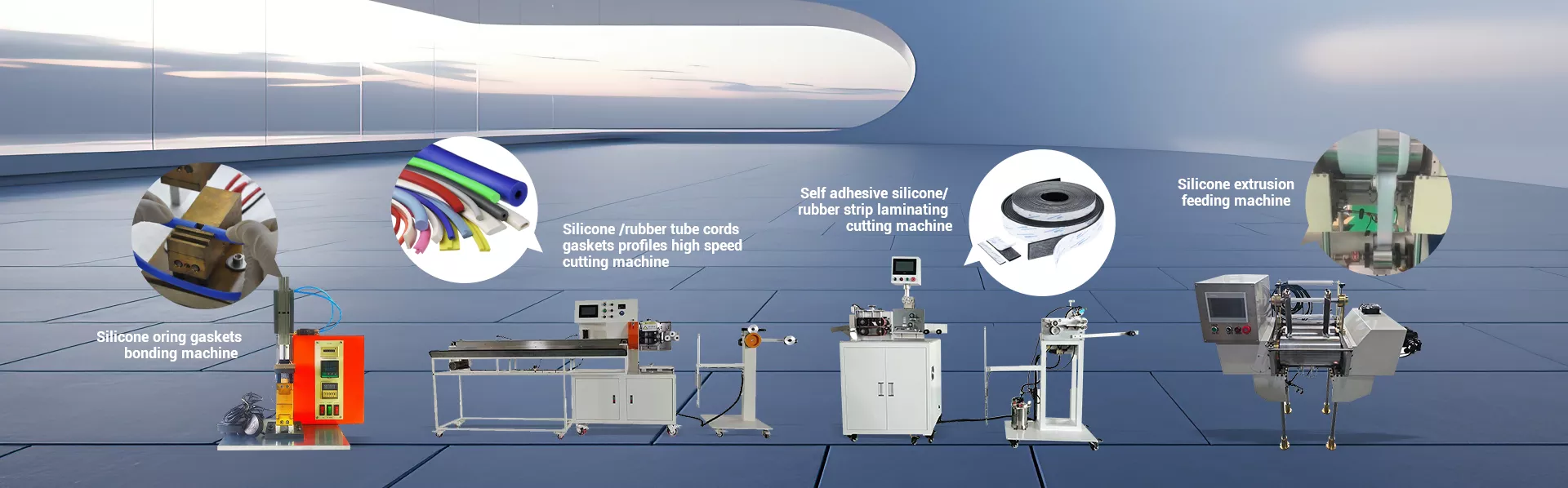

Silicone extrusion automatic feeding machine ES-059

The silicone extrusion automatic feeding machine ES-059 is designed specially for automatic feeding even quantity of raw silicone to silicone extrusion machines for processing which saves labour to feed manually . there are two mixing rollers that will mix raw silicone into sheet shapes and cut to fixed width sheet and feed to

the inlet of silicone extrusion machine . by multi sensors and monitoring device , this silicone extrusion auto feeder machine is capable of detecting overflow of raw silicone or lacking of raw silicone in the feeding process and adjustable its feeding speed to match with silicone extrusion machine speed .

The feeding speed ranges 20-100kg per hour , it is more suitable to feed htv raw silicone ranging shore hardness from 50 to 70 . this silicone extrusion automatic feeder machine works good for silicone extrusion machine type Φ50-Φ90 , the single input of raw silicone is 15-20kg . it is widely applicable to feed both platinum and DCBP silicone

Youtube video

This silicone rubber extrusion feeding machine applies with very big mixing rollers and driven by servo motors for stable and good performance , it is placed on top of the silicone extrusion machine and automatical adjust its feeding speed based on the speed of silicone extrusion machine

When there is lacking of material , it will trigger alarm and increase feeding speed , when there is overflow of raw silicone material , the silicone extrusion feeder machine will reduce its feeding speed .

Say goodbye to manual feeding , The ES-059 silicone extrusion feeder machine automatic feeding even quantity of silicone to silicone extrusion machine which is high productivity and labour saving .

【Technical Data】

Product name : Silicone extrusion automatic feeding machine

Model No.:ES-059

Advantage:Even quantity feeding , more convinent to feed and save labour

Voltage:220V 50/60HZ

Machine Power : 1000W

Operation system : 7 Inch Touch screen

Alarm mode : Lacking material alarm

Working mode : Single/Chain mode

Motor type : Servo motor

Feeding speed: Auto match with silicone extrusion machine speed

Applicable htv silicone shore harndess : 50 -70 shore hardness ( partial application to 40-80 shore hardness )

Applicable silicone extrusion machine : Φ50-Φ90

Applicable htv silicone type : Platinum cure/ DCBP

Single input htv silicone :15-20KG

Feeding speed: 20KG-100KG/H

Machine Net Weight : 260KG

Machine Dimension : L1350*W550*H1100MM

【Product Advantage】

1,Automatic feeding even quantity of raw silicones to silicone extrusion machine for extrusion processing

which is more covenient to feed .

2,Auto adjust feeding speed to match with silicone extrusion machine speed . the machine had equipped with multi sensors

when there is overflow of raw silicone material beneath the mixing roller , the feeding machine will reduce working speed, the when there is lacking raw silicone material , the machine will trigger alarm and increase feeding speed .

3,Widely applicable to all kinds of htv raw silicones ranges shore hardness 50 -70 shore hardness ( partial application to 40-80 shore hardness )

【Product Details】

1,Mixing roller &limit boards , this silicone rubber extrusion feeding machine applies with two big mixing rollers

for further mixing raw silicones and lead down to extrusion machine and there is also the limit boards

which avoids the raw silicones going sideways .

2,Cutting silicone roller &sensors the cutting silicone roller is placed beneath the mixing roller , it

will cut mixed raw silicone in fixed width lead down to the inlet of silicone extrusion machine . the cutting

width can be adjusted to feed different amount of raw silicone to extrusion machine . there is two types

sensors down the mixing rollers , the first type is material lacking sensor , when raw silicone runs out , it will trigger alarm

and increase feeding speed . the second type is raw silicone overflow sensor , when the raw silicone is overflooded , the

silicone extrusion auto feeder machine will reduce feeding speed .

3, Touch screen &servor motor ,this silicone rubber extrusion feeding machine applies with touch screen

which is easy to operate ,mainly it is to set the feeding speed , the machine is equipped with big servor motor

for excellent feeding performance.

4,Easy connection ,this silicone extrusion auto feeder machine can be easy connected to the silicone extrusion machine

for combined use ,below is connection plug to silicone extrusion machine . the working speed of feeder machine will match

with silicone extrusion machine .

Front View

Side View

Side View

Back View

【Warranty 】

As an silicone extrusion automatic feeding machine supplier , all the spare parts of the machine will have one year of free maintainance

by changing the spare parts for free and free shipping of spare parts to overseas clients starting from the issuing date of commercial invoice

after on line diagnosis .

【Packing】

1Set/Wooden case ,foam paddings will be put inside wooden case for safe overseas shipping

Home

Home  Inquiry Now

Inquiry Now Download

Download