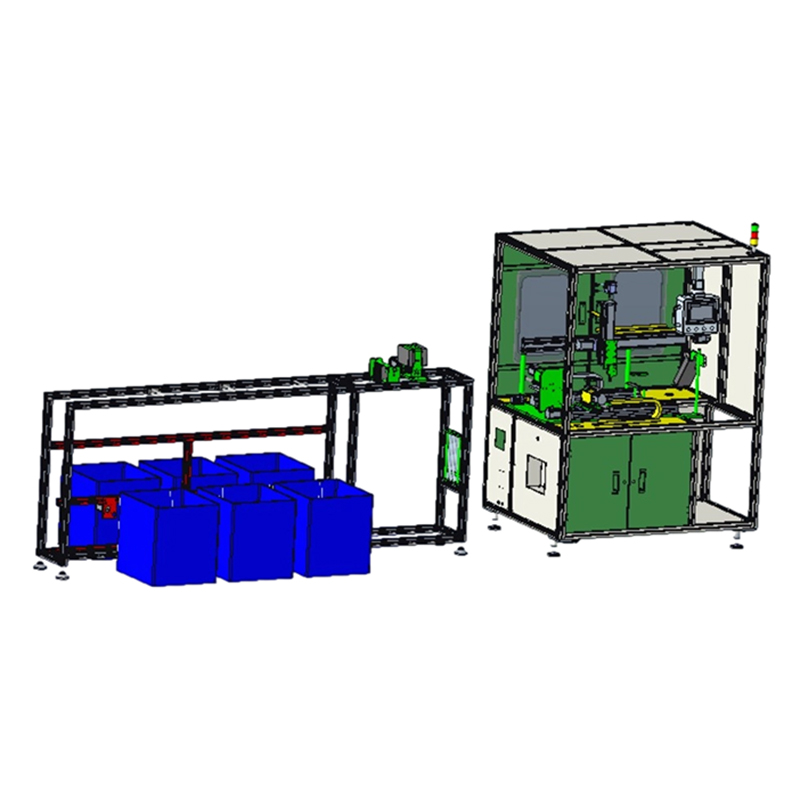

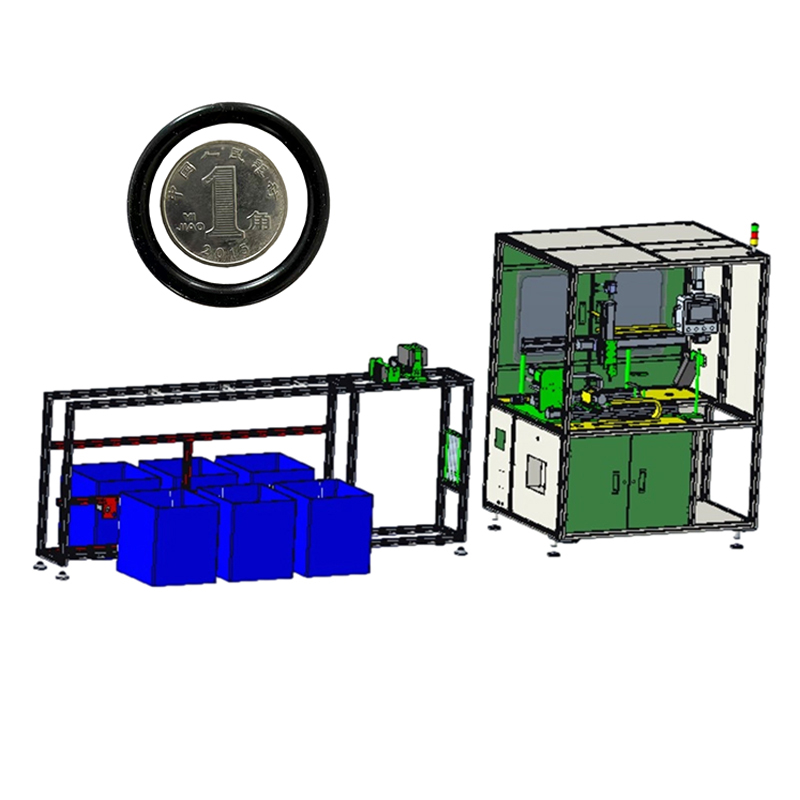

Small size silicone sponge O-Ring gaskets fully automatic cutting and bonding machine ES-060-5(67-300mm length)

The small size silicone sponge O-Ring gaskets fully automatic cutting and bonding machine ES-060-5(67-300mm length) is specially designed for automatic cutting and bonding small size silicone O Ring gaskets range 67-300mm cutting length . Compared to compression molded silicone O-Ring gaskets , this small size silicone O Ring gaskets automatic cutting and bonding machine can process silicone sponge gaskets and silicone tubes that compression molding can not do .

The productivity output reaches 900–1200 gaskets per hour by processing 5 pieces at once , it replaces labour of 3-6 six workers .

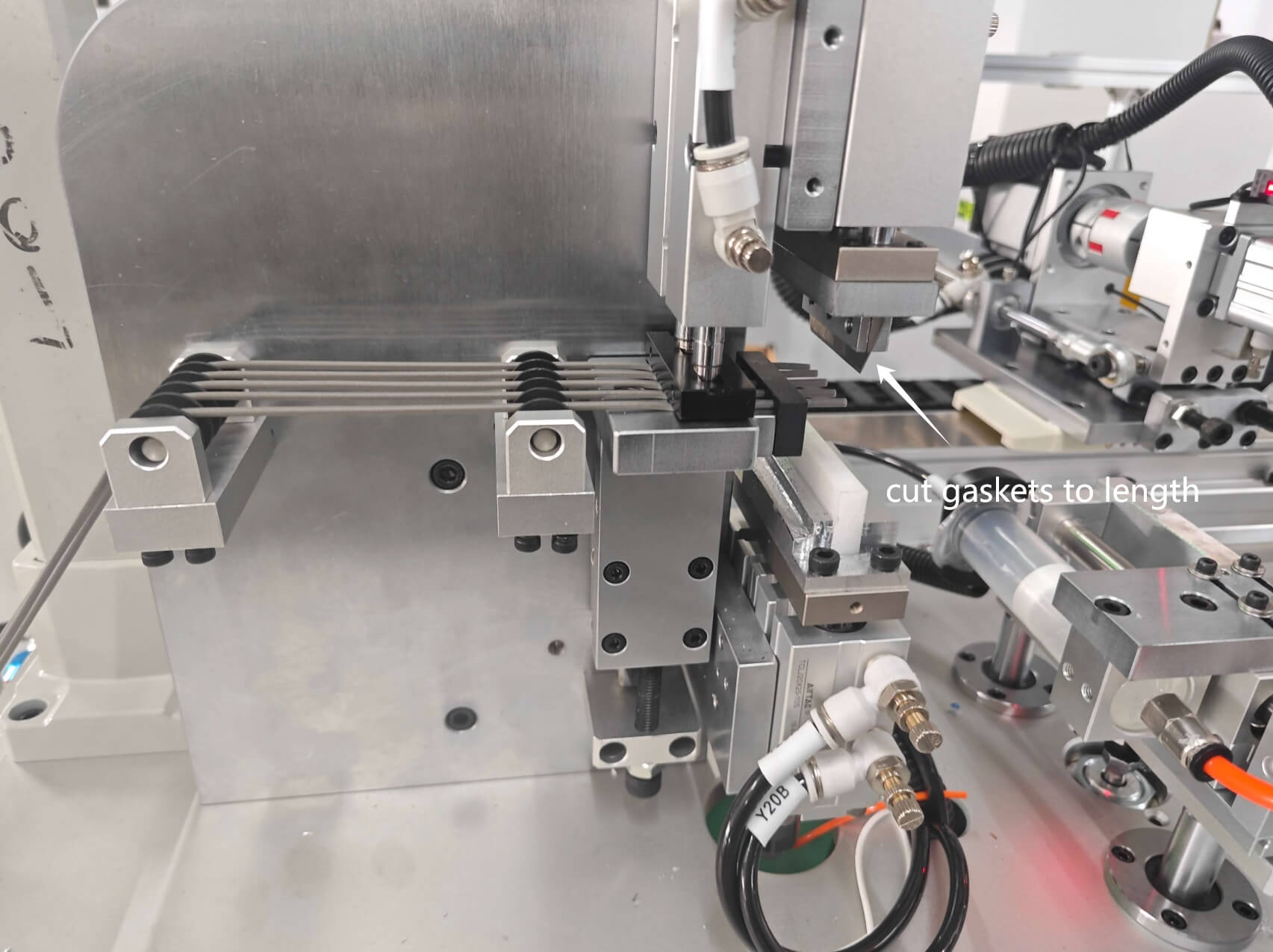

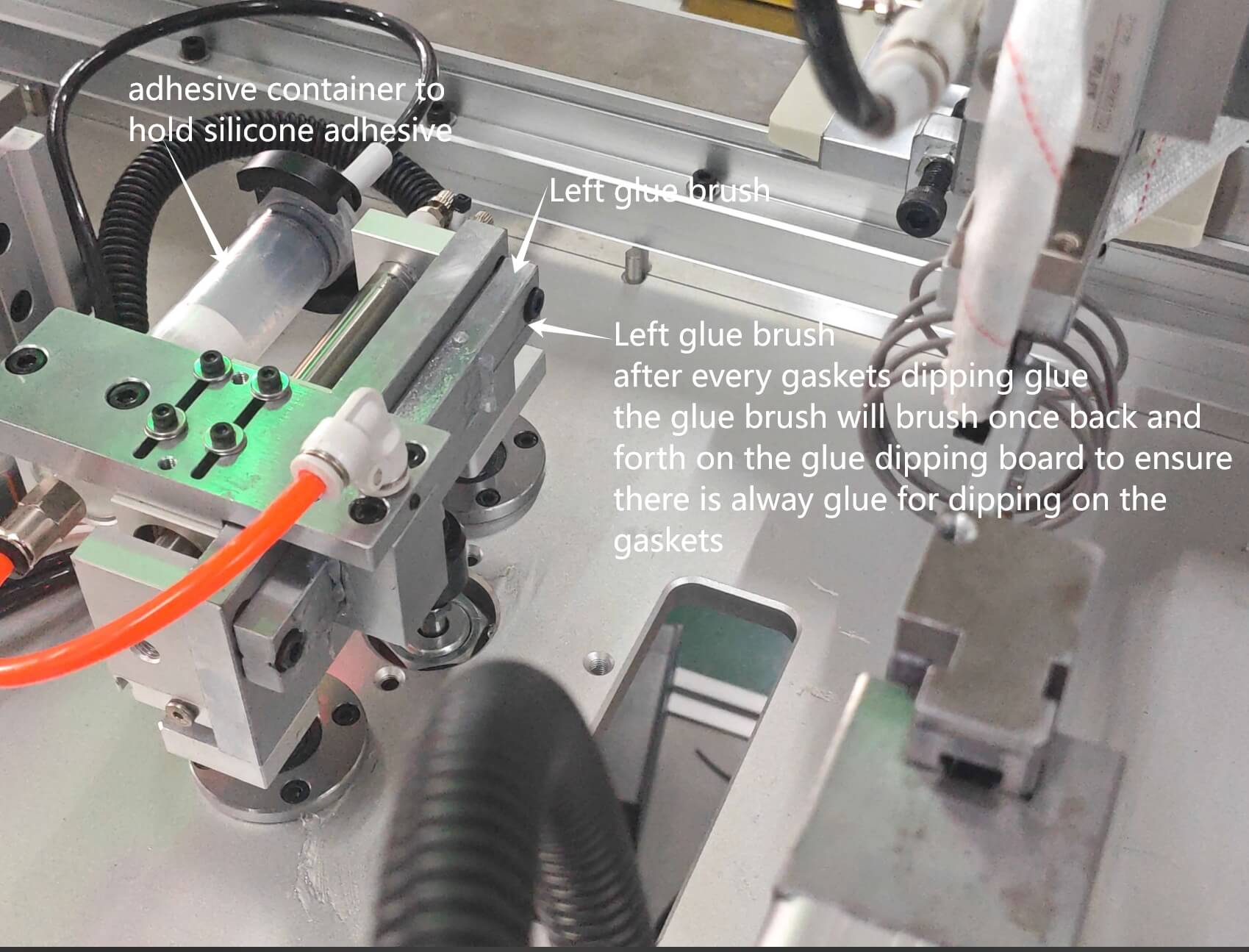

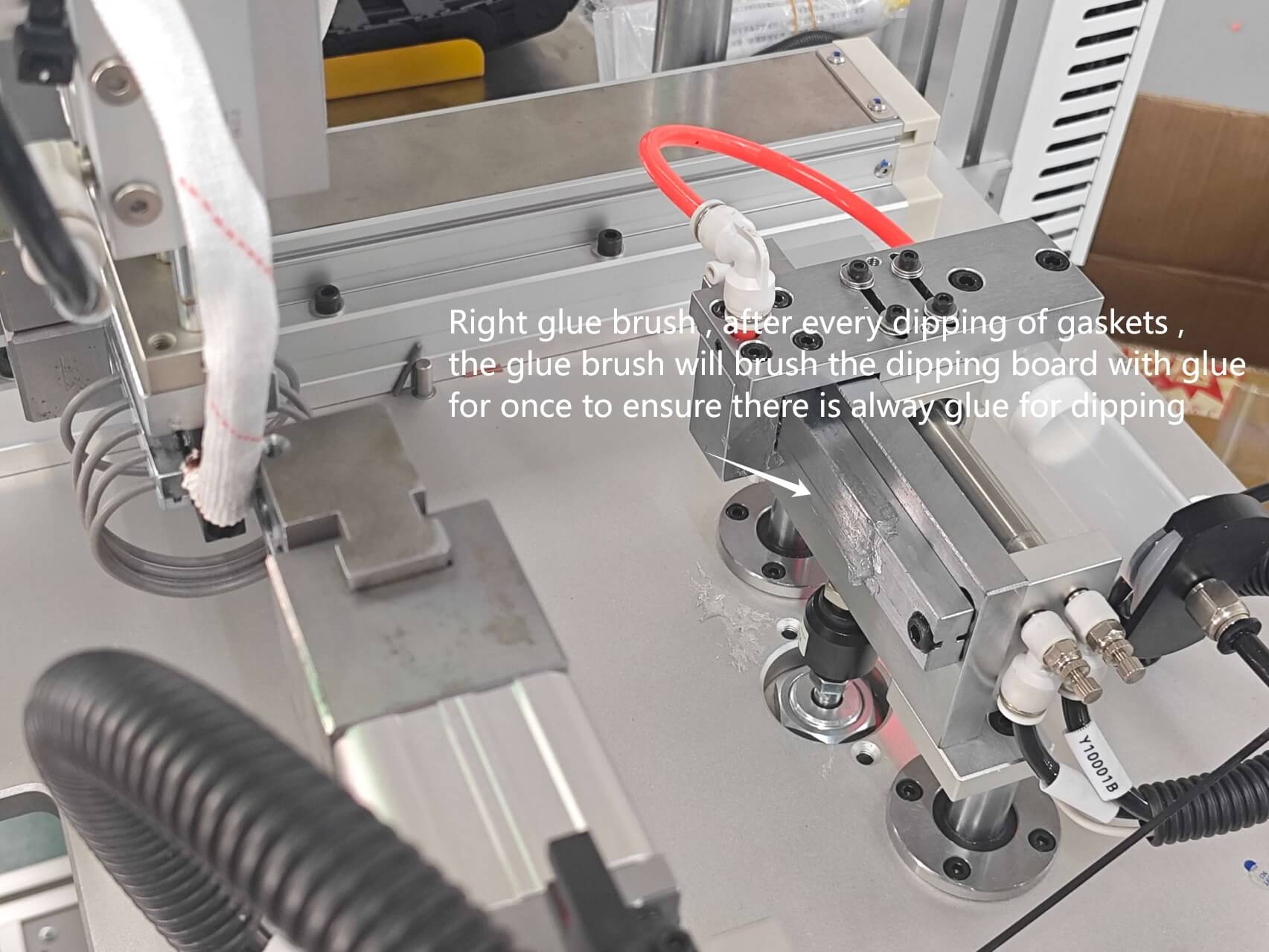

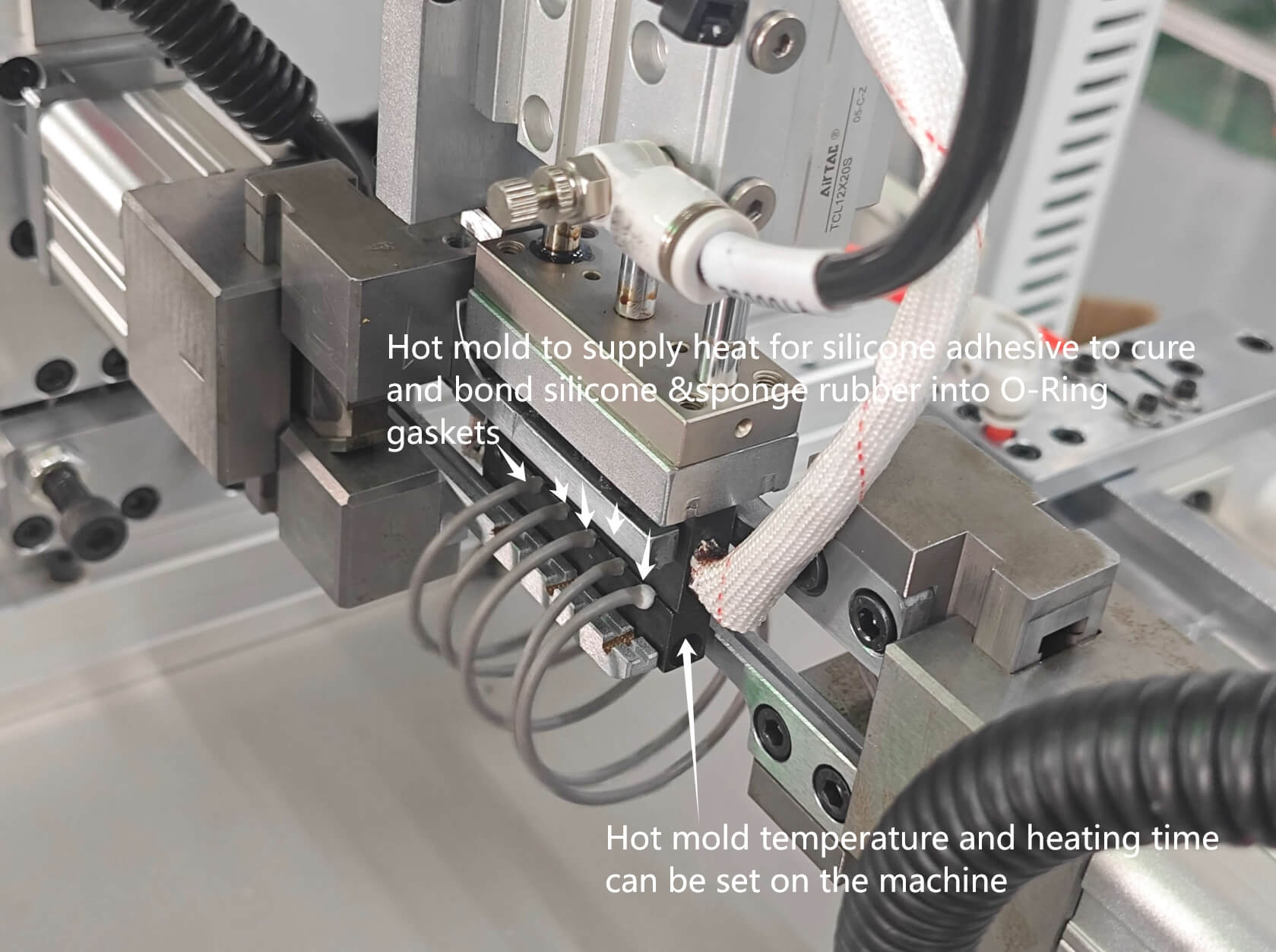

This small size silicone sponge O-Ring gaskets cutting and splicing machine combines auto feeding gaskets + auto cut gaskets to length + auto dipping silicone gaskets with silicone adhesive + auto putting silicone adhesive dipped gaskets into hot mold for bonding + auto collection finished bonded O-Ring gaskets in one machine .

Youtube video

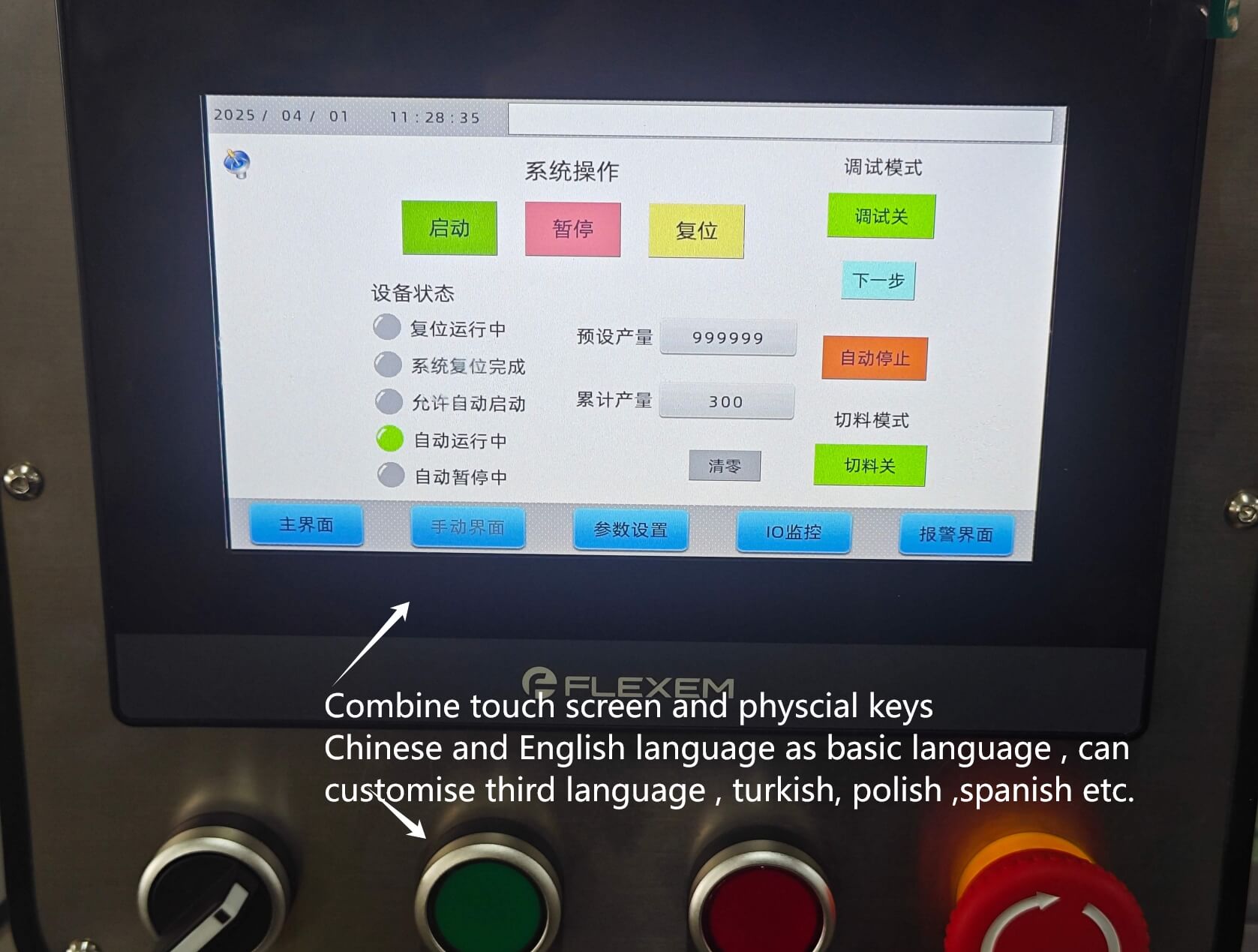

This small size silicone tube O-Ring gaskets automatic cutting and joining machine applies PLC touch screen controls which is easy to operate , customer can set product cutting length ,dipping glue times , hot mold heating temperature and heating times , total quantity &batch quantity etc . Both Chinese and Engish language are in the machine , A third language like polish , turkish , italian , spanish etc . can be customised if necessary.

The machine power is 4KW and motor uses servo motor for precision movement control , the gaskets diameter to be processed ranges 3-4mm and cutting length ranges 67-30mm for processing silicone sponge gaskets

and silicone rubber gaksets ranges 90mm--300mm cutting length .

The finished bonded silicone O-rings produced by this machine feature strong and stable bonding strength with clean ,high-quality joints and minimal adhesive residue. This is achieved through precisely engineered mold cavities tailored to the exact gasket size. Additionally, the cutting length is accurate with little cutting length tolerance. Overall, the machine offers excellent productivity and significant labor cost savings, making it an ideal and specialized solution for cutting and bonding small size Silicone O-Ring gaskets .

【Technical Data】

Product Name: Small size silicone sponge O-Ring gaskets fully automatic cutting and bonding machine (67-300mm length)

Model Number: ES-060-5

Cutting length range : 90mm to 300mm for silicone rubber gaskets , 67-300mm for sponge rubber gaskets

User-Friendly Operation: Touch screen interface with full Chinese &English language display, language can be customised based on different countries, parameter recording, display, and alarms. (Mold change required for different gaskets sizes.)

Labor Efficiency: One machine can replace the output of 3 to 6 workers.

Easy Mechanical Adjustment: It doesn’t require changing molds for cutting different length of same diameter sizes gaskets

Machine Power: 4KW

Motor Type: Servo motor

Control System: Xinje PLC

Automation Features: Automatic material feeding ,automatic cut gaskets to length ,dipping gaskets with silicone adhesive ,joining dipped glue gakets in hot mold for bonding and releasing finished bonded O-Ring gaskets . (Operator only needs to load material; all other operations are automated.)

Machine feature: 5 Pieces to be processed at the same time

One Cycle Time: 15 to 20 seconds per cycle (depending on product length and glue curing time);

Productivity :Ranges from 900 to 1200 units per hour (product length affects output).

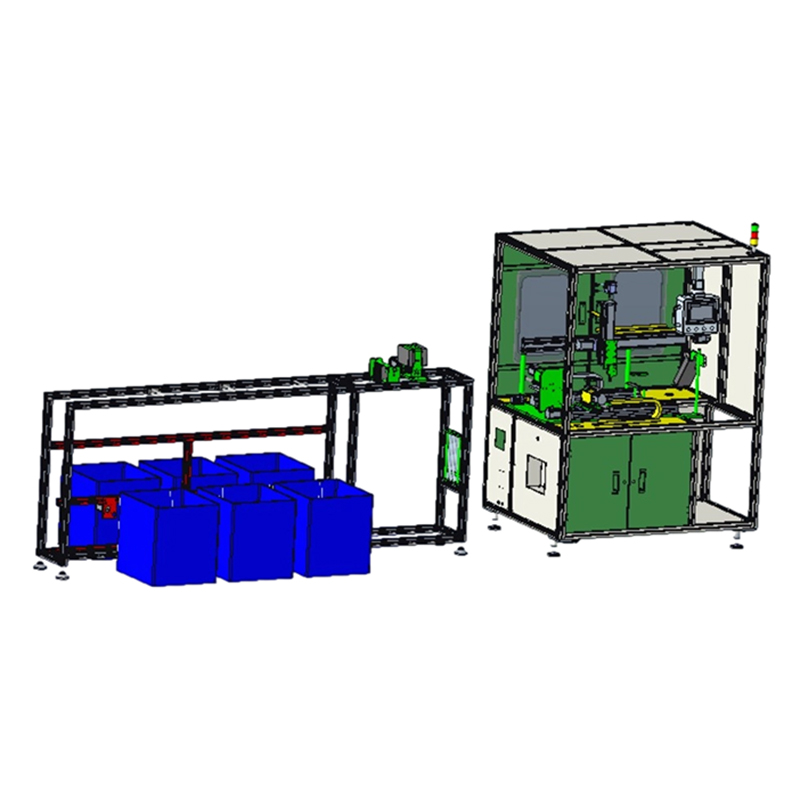

Machine Dimensions: L*W*H=1400mm *1100mm *1900mm

FEEDER Dimensions: L*W*H=3000mm *800mm * 1300mm

【Product Advantage 】

Compare to compression molded Silicone O-Ring gaskets , this small size silicone O-Ring gaskets fully automatic cutting and bonding machine had following advantage ,

1,Capable of making small size silicone sponge O-Ring gaskets and small size Silicone tube O-Ring gaskets as minimum as 67mm perimeter (Cutting length )

2, Higher productivity of 900-1200 pcs per hour with 5 pcs of silicone gaskets to be proessed at the same time

3, Lower mold cost ,the mold cost is very cheap for changing different diameter gaskets , for same diameter gaskets of different perimeter (cutting length) , it doesn't require changing molds , customer can set different cutting length and machine will cut to specifical length , besides, change mold time is less than 20 minutes .

4, Little wastage of silicone material compared to compression molding which also requires trimming edge post processing .

5,Strong bonding strength & Good joinit quality and little cutting length tolerance

【Product Details】

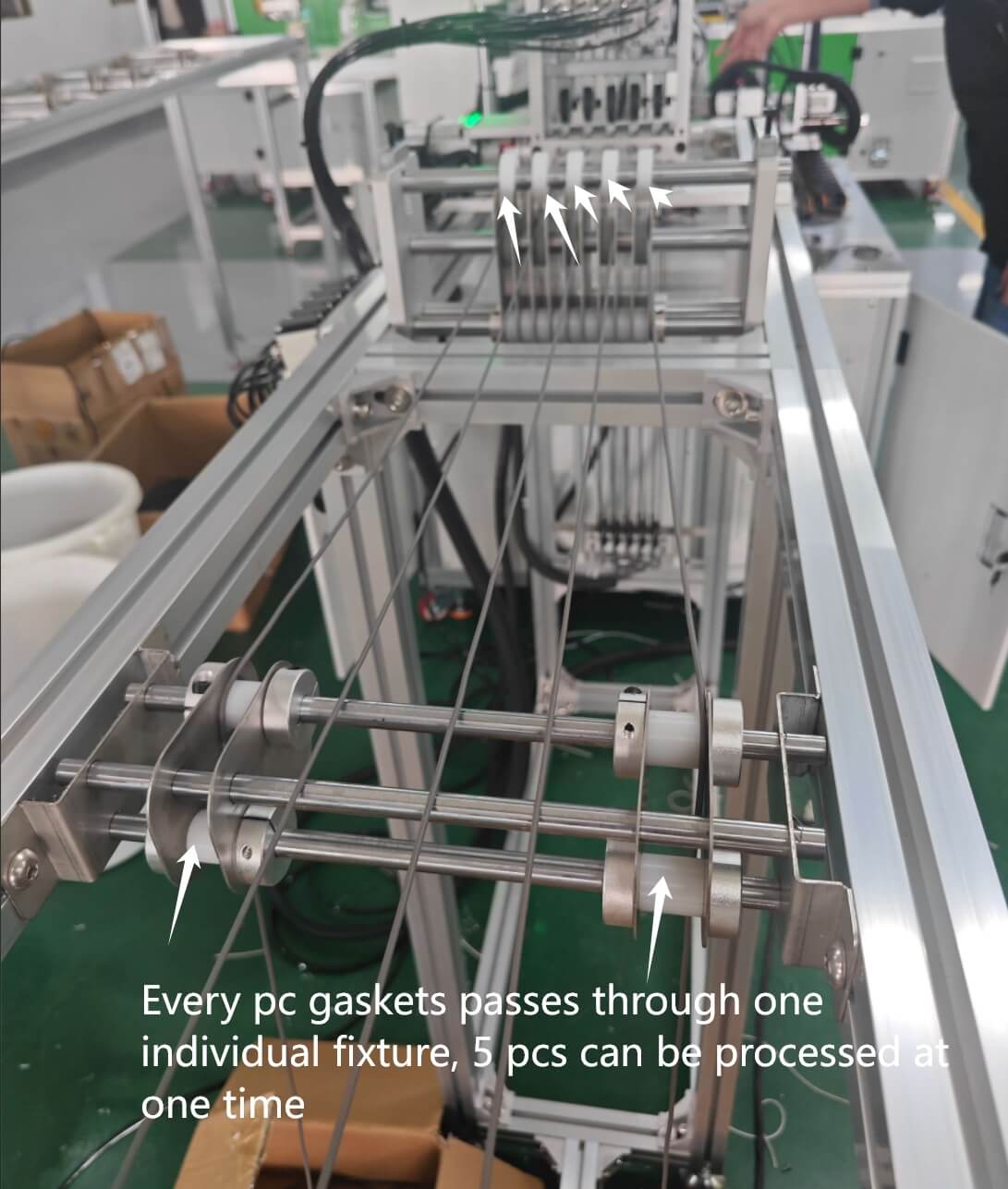

1,Feeding 5pcs silicone gaskets by feeder shelf, every pc silicone gaskets are fed separately through individual fixtures ,they are fed in one alignment and do not cross each other ,this enables 5 pcs of silicone &sponge gaskets to be fed at the same time to increase the productivity .

Every pc gaskets passes through one individual fixture,all pcs gaskets are fed in one alignment .

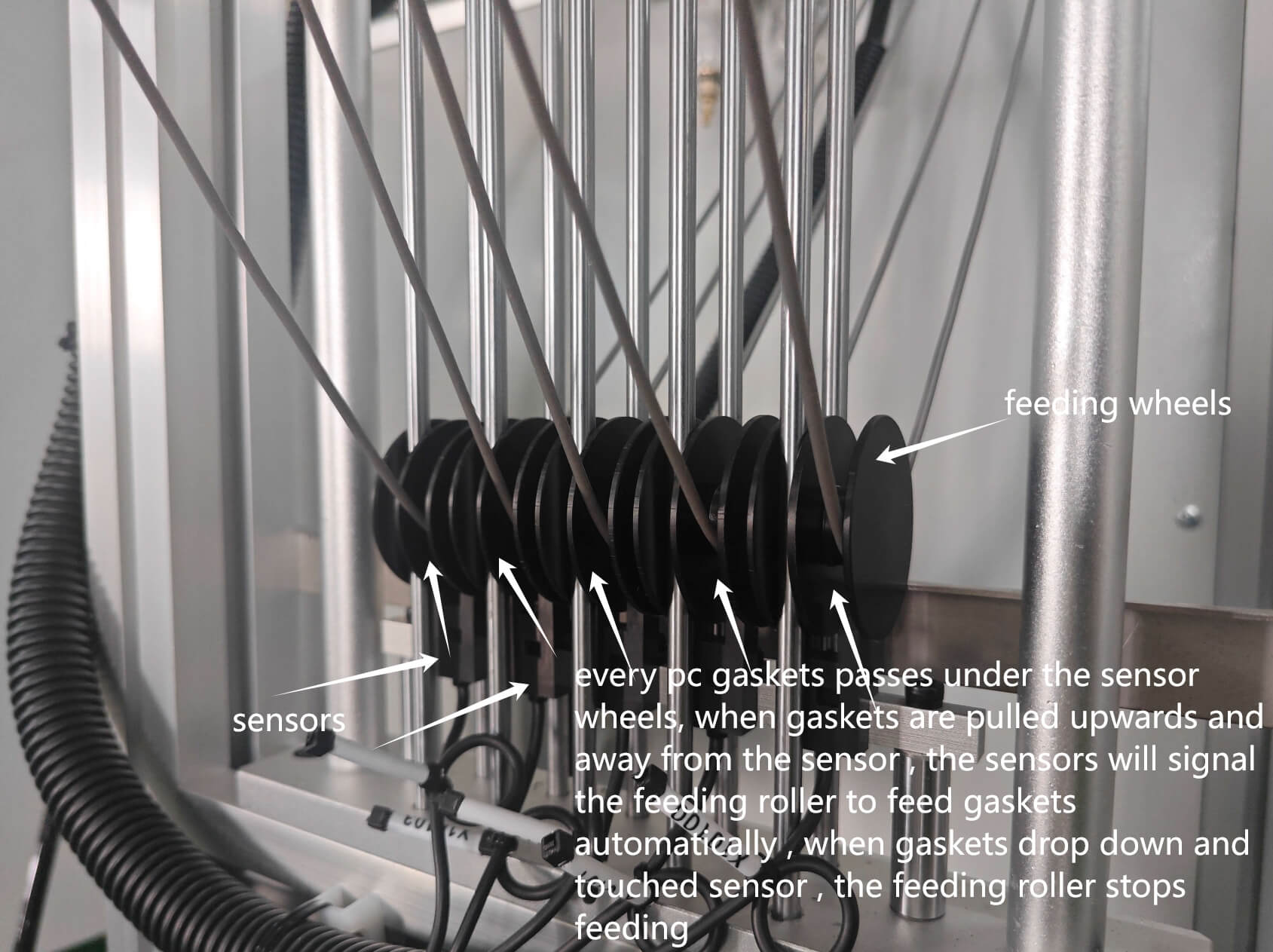

One feeder roller to feed one pc gasket forward for procesing ,they feed based on signal from sensors to ensure there is no tension during feeding process to avoid cutting length tolerance .

Every pc gaskets passes under the sensor wheels ,when gaskets are pulled upwards and away from the sensors, the sensors will signal the feeding rollers to feed gaskets automatically , when gaskets drop down and touched sensors , the feeding rollers stops the feeding. This process will avoid the pulling and tension during feeding process and maintains cutting length precision .

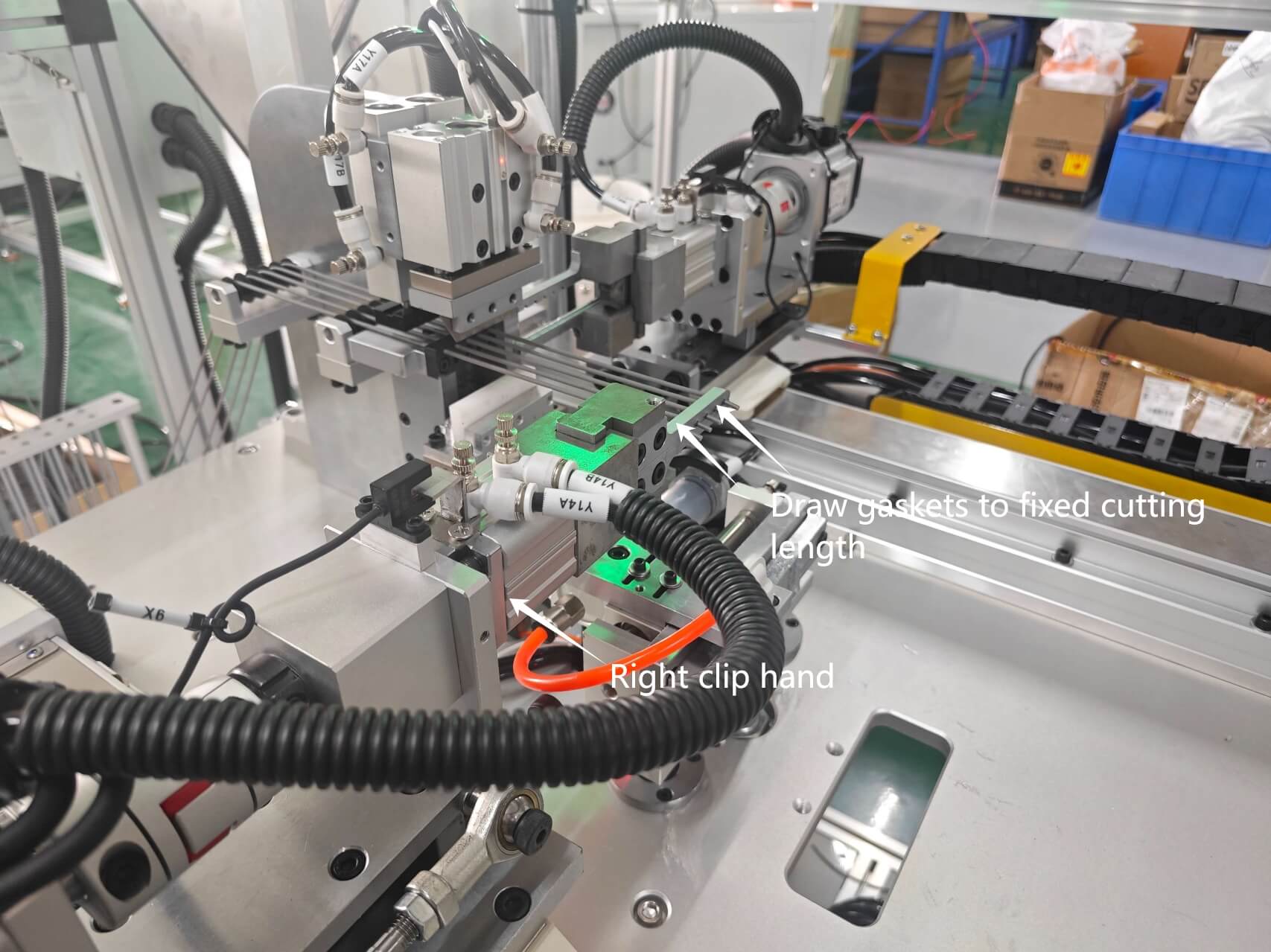

2,Draw gaskets to fixed cutting length , , the righ clip hands of this Small silicone O-Ring seals fully automatic joining machine will draw 5pcs gaskets to fixed cutting length and cut off ,the cutting length will have little tolerance and cutting edge is straight for bonding . the drawing length speed can also be set if we are dealing with some very soft sponge material for ensuring cutting length precision . different cutting length rangs 67-300mm (2-4mm diameter) can be set on the machine freely without changing mold . it only requires changing molds when the machine process different type diameter gaskets .

3,Dipping both ends gaskets with silicone adhesive , the clip hands will dip the gaskets with silicone adhesive against the glue dipping boards . both the left and right glue brush will brush glue back and forth for once on the glue dipping boards after every glue dipping to ensure there is always glue on the glue dipping boards for dipping , the dipping glue times can be set on the machine freely .

Dipping gaskets with silicone adhesive before hot mold bonding .

4, Place dipped-glue gaskets in the hot mold ,the two clip hands of this small size silicone tube O-Ring gaskets automatic cutting and joining machine will place the glue dipped gaskets in the hot mold for silicone glue to cure and form a good bond for joined Silicone &sponge O-Ring gaskets . the heating temperature and heating time of the hot mold can bet set on the machine based on different type gaskets .

5, Collection of bonded O-Ring gaskets , the finished bonded O-Ring gaskets will be taken off from the hot mold by the collection hand , the collection hand will foward the bonded O-Ring gasekets to collection conveyor belts bands or direclty to collection boxes

6 , PLC touch screen, this small size silicone sponge O-Ring gaskets cutting and splicing machine applies with PLC touch screen which is easy to operate the machine ,customer can set product prameters, exact cutting length , dipping glue times , heating temperature ,heating time , machine general speed ,total quantity .etc . Both Chinese and English language will be loaded on the touch screen ,customer can choose a third language in their country like polish , spanish ,turkish , italian etc.we will customise the language on the touch screen .

Front View

【Warranty 】

As a small size silicone sponge O-Ring gaskets fully automatic cutting and bonding machine (67-300mm length)supplier , all the spare parts of the ES-060-1 machine will have one year of free maintainance by changing the spare parts for free and free shipping of spare parts to overseas clients starting from the issuing date of commercial invoice after on line diagnosis .

【Packing】

1Set/Wooden case ,foam paddings will be put inside wooden case for safe overseas shipping ,G.W after packing wooden case is 1T, Wooden case dimension is (L3050+W2150+H2150MM)

Home

Home

Inquiry Now

Inquiry Now Download

Download