Silicone gaskets htv silicone adhesive ES-100-AB

【Product Description】

The silicone gaskets htv silicone adhesive ES-100-AB is made for the fast bonding of silicone to silicone to make a silicone o ring gaskets , The silicone gaskets adhesive cures in high temperature of 175 degrees supported by a heat press bonding machine for 8-10 seconds . the cured adhesive has little trace on the bonding area. the cured silicone adhesive is waterproof and high temperature resistance .

The silicone to silicone bonding agent is platinum addtion HTV liquid Silicone adhesive ,this silicone gaskets bonding agent has excellent elongation rate and anti-ageing after adhesive curing , the silicone gaskets bonding agent is widely used on the bonding of all kinds of silicone extrusion profiles which is platinum system or peroxide system, typically on silicone tubings and silicone gaskets , etc.

【Product Advantage】

* Fast and stable bonding with adhesive curing in 8-10 seconds

* Long storage time after adhesive mixture for more than one month

* Food and medical grade , high temperature resistant.

* No bonding trace on the joint line , making a nice silicone o ring .

【Physical properties】

Appearance:Colorless transparent gel

Component:Double component (A: Gel , B: Catalyst )

Viscosity:400000CPS±5000

【Addition Rate】

100:2(Based on gel weight)

【Processing】

1, Clean the substrates and leave dry ,better use tolune or other volatile solvent ,if solvent is not available , cleaning is not needed ,Mix the ES-100-AB with weight ratio (Gel : Catalysts =100:2) evenly.,

Apply a little adhesive on the silicone bonding surfaces,the heating temperature is 170±10℃ with curing temperature 8-10 seconds . (with too higher temperature ,the platinum curing will be dramatic which cause the cured adhesive elongation rate go down . with lower temperature , the adhesive curing time will be lengthened which will compromise the productivity

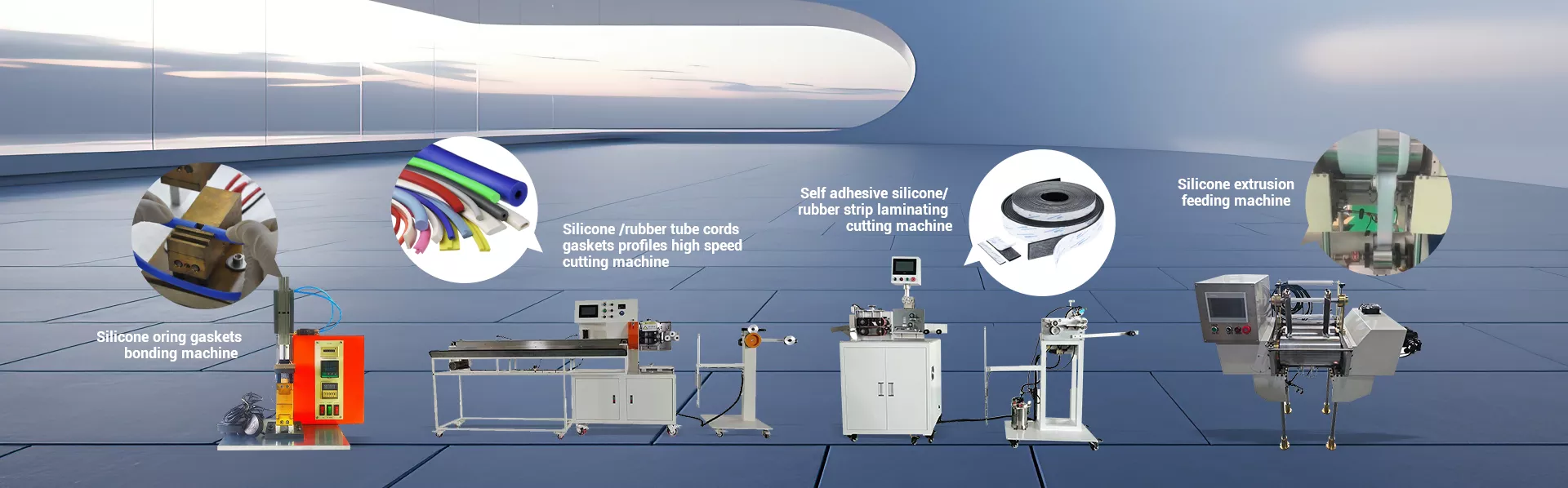

Fix the groove-opened mold on the heating plate,Turn on power and connect the air source,Set the heating temperature on the temperature controller(based on product size), Set the time which decide the heating time needed for bonding the silicone gaskets,Mixed evenly the silicone adhesive ES-100-A and ES-100-B and distribute the silicone adhesive ES-100-AB evenly on the PET Sheet for better dipping and near amount of adhesive consumption for each dipping .

2, Preheat by pressing the silicone gaskets ends against the hot copper mold for 2-3 second for a more strengthened bond.

3, Dipping the two silicone gaskets ends with silicone adhesive on the PET Sheet .

4, Place the silicone gaskets in the copper mold and press the silicone gaskets ends joining together to secure they contact well for good bond.

5, Tread on the foot padel and the upper mold will come closing down, wait for heating 8-10 seconds and the bonding process is completed .

6,take out the bonded silicone O rings from the mold after the upper mold goes up .

【Storage】

The product shelf life of the Silicone gaskets htv silicone adhesive is 6 Months after AB mixture, The product should be stored in the refrigerator with temperature around 10 ℃ after AB mixture.

【Packing】

1KG/Bottle , foam paddings will be placed around the carton to protect it against rough handling .

【Safety Note】

Silicone gaskets htv silicone adhesive ES-100-AB contains the platinum catalyst, In the curing process , it should avoid contact with N,P,S , such organic compound . Sn, Pb ,Hg, Sb, Bi ,As, such heavy metal like Ionic compound. And also avoid contact with acetenyl of Unsaturated base. Otherwise , it will cause bad cure of the adhesive . Thus ,The compatibility test of adhesive and substrates is needed. Please keep away direct contact with eyes. If contacted , please wash with clean water asap or call the doctor immediately.

Home

Home  Inquiry Now

Inquiry Now Download

Download