The Silicone corner bonding machine ES-070

The Silicone corner bonding machine ES-070 is designed for corner jointing of silicone profiles efficiently and with nice joint quality by making the right mold .

This silicone profile corner bonding press machine applies with movable down mold which ensures the silicone profiles can get off from the mold easily after corner bonding .in the meantime , the movable down mold apply horizonal pressure to the corner joint which ensures the silicone adhesive are heated completely for good joint of silicone profile corners .

This silicone corner bonding machine supplies high temperature up to 400 degrees , the mold is made of copper which is of high heat tranfer efficiency. the cavity size in the mold is made based on customer's silicone profile sizes .so the joint quality is nice . the bonding mold pressure is 25kg of saftey pressure to worker use .

This Silicone corner jointing machine is practical to use for extrusion silicone manufacturers to make corner joint of their silicone profiles and ensures high productivity as well .

【Technical data】

Model No.: ES-070

Product name : Silicone corner bonding machine

Feature : Both upper mold and down mold movable for good joining silicon profile into corners

Mold Material : Copper

Type: Air cylinder reinforced type

Upper Mold size: 40*80*13mm(Mold Thickness Ajustable)

Down mold size : 40*80*13mm(Mold Thickness Adjustable)

Copper Mold Temperature Range:0-400℃

Heating time range : Set heating time freely in seconds/minutes/hours

The Fast working frequency:1000 times/hour

Working Air Pressure: 0.7mpa

Maximum mold pressure :25KG safety pressure

Power Input: AC220V 1200W

Net weight: :25KGS

Machine Size: L400*W300*H620mm

【Product Advantage】

1, Both upper mold and down mold movable to ensure the silicone profile are heated completely for a good joint

and the movable down mold can move backbards after heat bonding which is easy for bonded silicone corner profile to get off from the mold .

2, High productivity,the silicone profile corner bonding press machine is practical to use and ensures high productivity of bonding silicone corner profiles

3,Nice joint quality by making cavity size based on the silicone profile size to hold them steady for bonding and the cutting edge should be cut straight

by the cutting machine for nice bonding quality .

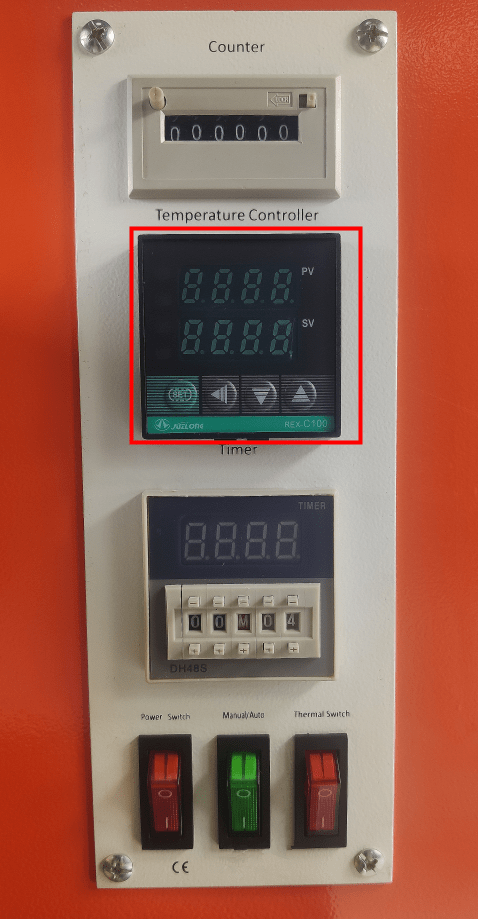

【Product detail 】

1, Easy to use control board , the slicone gasket corner welding press machine will be easy to use

customer can set the heat time freely ,heat temperature from 0-400 ℃,the machine can also do

counts for how many pcs of silicone orings had been bonded .

2,Air source connection , the upper mold had long travel range and linked to air source

which issues heav air pressure and gurantees the silicone orings are bonded sufficiently .

3, Movable down mold ,the standard bonding press machine only has movable upper mold pressing down

this silicone profile corner splicing machine has movable down mold which press to close horizonally to

heat cure the silicone adhesive completely for good jointing of silicone profile into corners and move

backwards for easy release of bonded silicone profile from the hot mold .

【Front view】

【Side view】

【Side view】

【Back view】

【Warranty】

All the spare parts of the Silicone corner bonding machine machine will have one year of free maintainance by changing the spare parts for free

and free shipping of spare parts to overseas clients starting from the issuing date of commercial invoice after on line diagnosis .

【Packing】

Wooden Case Packing for overseas safe shipping , 1SET /WOODEN CASE

Home

Home  Inquiry Now

Inquiry Now Download

Download