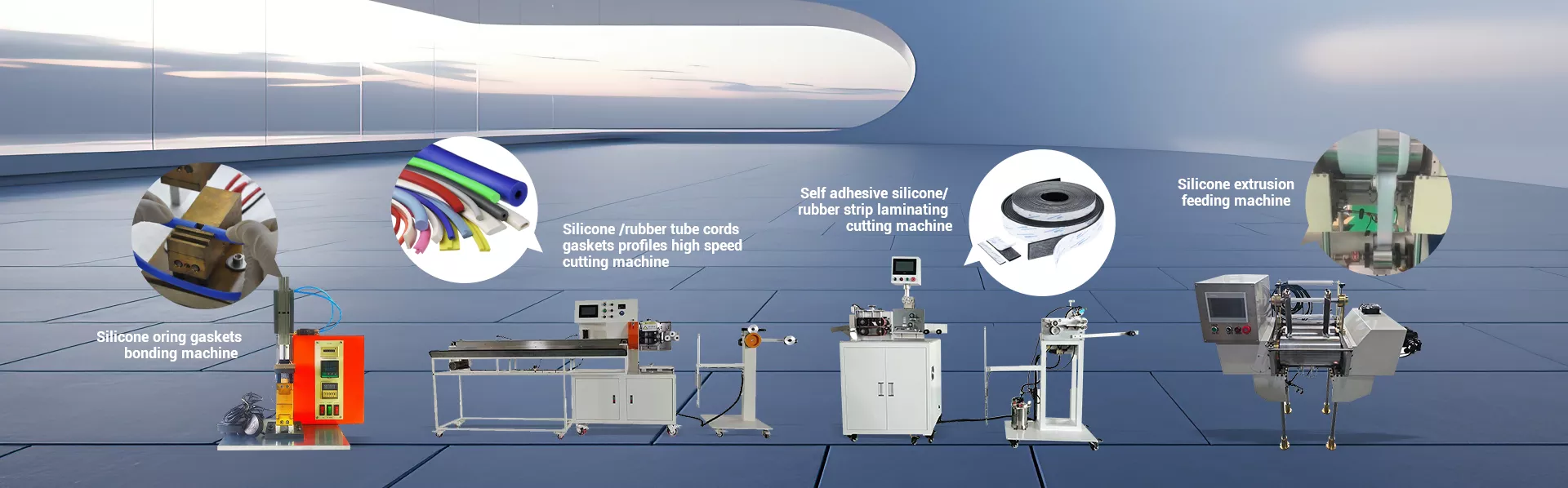

The Angle cut silicone tube high precision cutting machine ES-041

The angle cut silicone tube high precision cutting machine ES-041 is heavy machine that designed for automatic cutting of medical silicone tubes ,silicone cords and other extruded silicone profiles with high cutting length accuracy and 0-90 degree angle cut and straight to be performed on this machine freely. we have straight cutting type and angle &straight cut type for customer to choose from .

The cutting OD is 3mm-25mm for this automatic silicone tube precise cutter machine , the cutting length ranges 0.1-99999.9mm , the cutting length accuracy reaches +_0.1mm . the cutting speed is high for this medical silicone tube cords heavy cutter machine and cutting speed can be adjusted at will . the medical silicone cords accurate cutter machine applies with servor motors with stable working performance . It had been equiped with self feeder + sensor from the back to send in cutting material and avoids tension of extruded silicone during cutting process

This automatic silicone tube profile cutter machine can also be customised to cut irregular shapes of silicone profiles too , it can do all kinds of angle cut with customisation of rotation knife.

Youtube video

0-90 Angle cut &Straight cutting type machine ES-041

Straight cutting type machine ES-041

The machine applies with double transport bands for transportation of the extruded silicone tube cords , the main advantage of the double transport bands design is that it secures precision transportation and precise length cutting backed up by alternate servor motor .Contrary to the traditional rolling method (positive roller to lead negative roller), the double tranport bands had very large contact area with the cutting material and both rollers is positive , this performance gurantees cutting length precision.

2, The transport bands design can reduce the distortion of the cutting material caused by roller pressing when transported by the traditional rollers. meanwhile ,the distance of the two transport bands can be adjusted to let the machine become suitable to cut different sizes of silicone tubes or silicone cords ,silicone sponge cords .

【Technical Data】

Product name : Angle cut silicone tube high precision cutting machine

Brand : ESMAI Motor : servor motor + sensor

Model No.: ES-041 Voltage: 110V/220V

Machine type : 0-90 °Angle &Straight cut type and straight cut type Power: 1650W

Cutting Speed : 0-999pcs / minute Cutting OD: 3mm-25mm

Cutting length precision: +_0.1mm Net Weigth : 156KG

Cutting Length: 0.1-99999.9mm Product dimension : 1300*550*1560mm (L*W*H)

【Product Advantage】

1, High precision cutting length for medical silicone tubes cords of customers with high cutting length precision requirement

2, 0-90 Degree bevel angle cut can be set at free on the machine

3, Feeder + Sensor + Cutting in one heavy machine ,easy to operate .

【Product Detail 】

1,Double transport bands which had large contacting surface with the silicone tube or cords ,profiles to ensure there is no slipping during transporting

and consequently avoid length tolerance due to the softness physical property of the extruded silicone . the tansport band surface are made with special finish

which increase the abrasion when contacting with the extruded silicone .

2, Rotation knife to adjust the angle cut from 0-90 degree ,customer can prepare the fixture molds with groove line made first and set their angle for cutting on the machine freely

2, Top ajustment screws to adjust double transport bands distance so as to fit and hold tightly the OD sizes of different extruded silicone tubes ,cords .

wide applicable to OD size ranges 3mm - 25 mm

3, Feeder + sensor from the back to send in silicone tubes&cords ,the feeder will accept signal from the sensor to send in cutting material instantly , the sensor can sense if there the cutting material runs out from the knife and signal the feeder to send in cutting material so the silicone tube cords will always remain in a loose status , it avoids the tension during material transport cutting process and ensures cutting length precision .

4, Cutting fixture mold which hold the silicone tube cords profiles just well from swaying or cocky and thus gurantees vertical straight cross section cutting edge finish

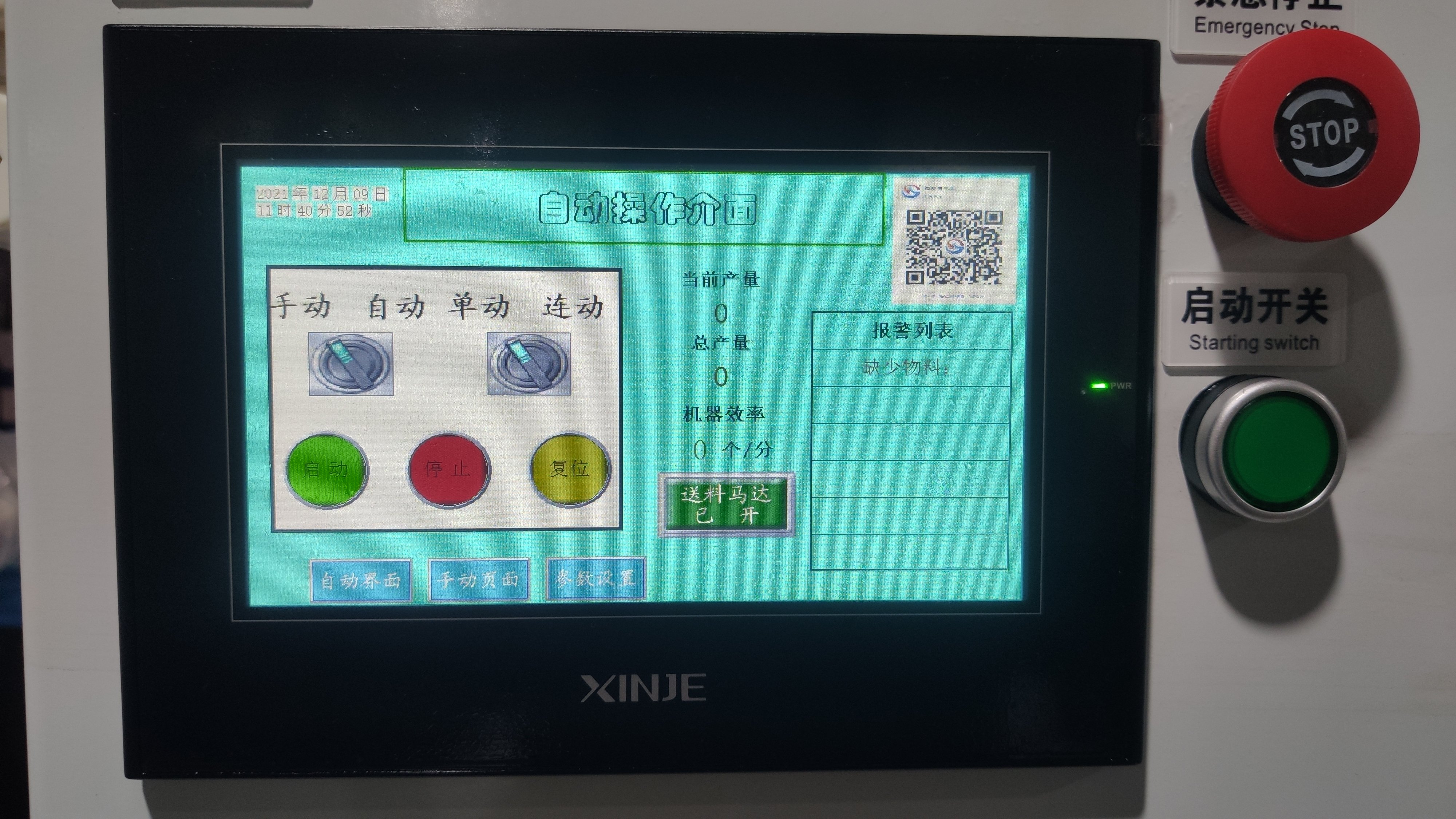

5,Simplified control panel ,the cutting length ,knife cutting speed, feeder speed ,total cutting amount can all be set on the digital display touch screen

the control keys are simplified and easy to understand and operate.

Front View

Side View

Side View

Back view

【Warranty 】

As a professional angle cut silicone tube high precision cutting machine manufacturer , all the spare parts of the ES-041 except the knife will have one year of free maintainance by changing the spare parts for free and free shipping of spare parts to overseas clients starting from the issuing date of commercial invoice after on line diagnosis .

【Packing】

1Set/Wooden case ,foam paddings will be put inside wooden case for safe overseas shipping

Home

Home

Inquiry Now

Inquiry Now Download

Download