Adhesive silicone rubber strip laminating cutting machine ES-087

The Adhesive silicone rubber strip laminating cutting machine ES-087 is designed for automatically feeding silicone and rubber strips , automatically coating primer on the silicone and rubber strip surface and auto laminate silicone or rubber strips with 3m double side tapes and auto cut laminated material to fixed precision cutting length .

The best advantage of this machine is that it can laminate big width material up to 100mm by the roller coating primer method , the laminated silicone and rubber strip is good adhesion and laminated surface is smooth and flat without dislocation .

Youtube video

laminated material is smooth and flat laminated surface without dislocation .

laminated and cut sample (straight cut cutting edge &same cutting length )

This adhesive silicone rubber strip laminating cutting machine applies sensor for feeding silicone or rubber material automatically and also applies material lacking sensor under the 3m tape roll , when there is lack of 3m tapes , it will signal the machine to stop working and raise alarm for worker to load on new material .

The cutting length ranges 1-99999.99mm ,lamination material thickness is 1-25mm , the lamination speed is adjustable , the average lamination speed is 15-30 meters per hour . the lamination device applies with servo motor control which is good quality and ensures stable performance .

This adhesive silicone rubber strip laminating cutting machine ES-087 is good qualtiy and labour saving which is designed specially for laminating big width rubber and silicone strips with double side tapes with roller coating primer method . the roller coats primer more evenly on the rubber and silicone strips for ensuring good adhesion with 3 m tapes .

【Technical Data】

Product name: Adhesive silicone rubber strip laminating cutting machine

Model No. : ES-087 (Big width)

Function : Coat silicone or rubber surface with primer +Laminate silicone or rubber with double tape +

Cut silicone or rubber strip into length

Primer coating method : Roller coating

Touch screen :PLC Touch screen& Key pressing

Voltage:220V

Power : 2.8KW

Motor type :Laminating motor of Servo motor 1.8kw ,feeding motor of steppingm motor 1kw

Laminating material thickness:1mm-25mm (Can be customised)

Laminating material width :2mm- 100mm

Cutting length range: 1-99999.9mm

Cutting length precision: +-1mm (Based on 1mter length silicone strip)

Productivity/Speed :15-30 meters/min (based on product type)

Machine Net weight: 210kg

Machine dimension:

Laminating machine :L*W*H=95*75*155 CM

Primer coating&feeding machine : L*W*H=160*65*120CM

【Product Advantage】

1,Auto feeding material + auto primer coating on the silicone or rubber strips + auto lamination of silicone or rubber with double side tapes +

auto cutting laminated material to length in one machine , labour saving and high productivity .

2,Large lamination width up to 100mm which allows this ES-087 machine to laminate big width silicone or rubber strips by the roller coating

primer method .

3,Straight cutting edge & precision cutting length & good lamination material without dislocation and smooth lamination surface.

【Product Details】

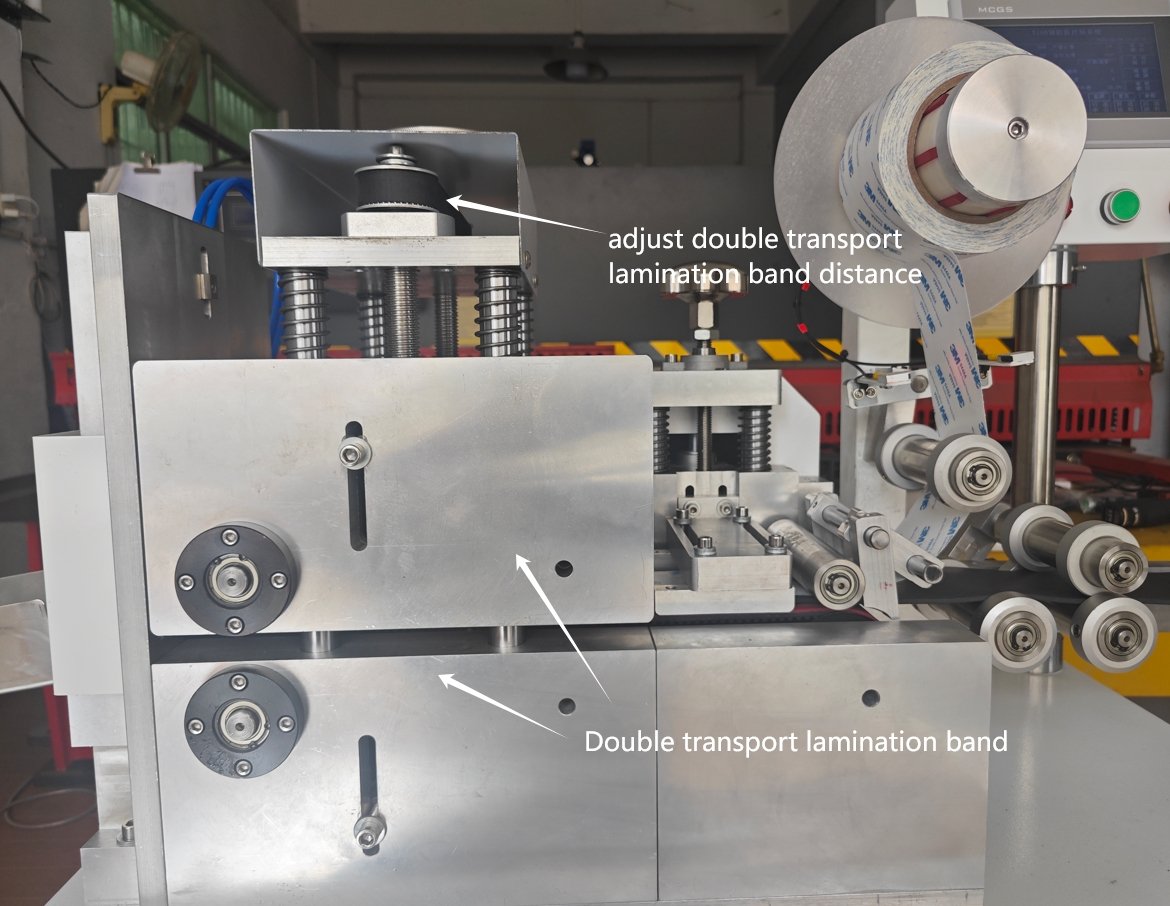

1,Double transport lamination bands , this adhesive backed rubber strip with 3m tape laminator machine applies with

double transport lamination bands of 100mm width which allows it to laminate large width strips , the lamination

is driven by servo motor of 1.8KW, The lamination pressure can be adjusted on the top screws based on the thickness

of silicone and rubber strips .

2 , 3M tape holder& material lacking sensor , the 3m tape holder is placed on top of the machine , it comes down

to join with silicone and rubber strips for lamination , there is the material lacking sensor , it can sensor the lacking 3m tape material

and signal the machine to stop working when out of 3m tape material .

3, Feeding sensor &feeding roller, there is a feeding sensor between the lamination machine and feeding&primer

coating machine .the feeding sensor can sensor the material coming to the upper area and signal the feeding roller to feed

material automatically ,when the material drops down ,the feeding speed will be reduced automatically.

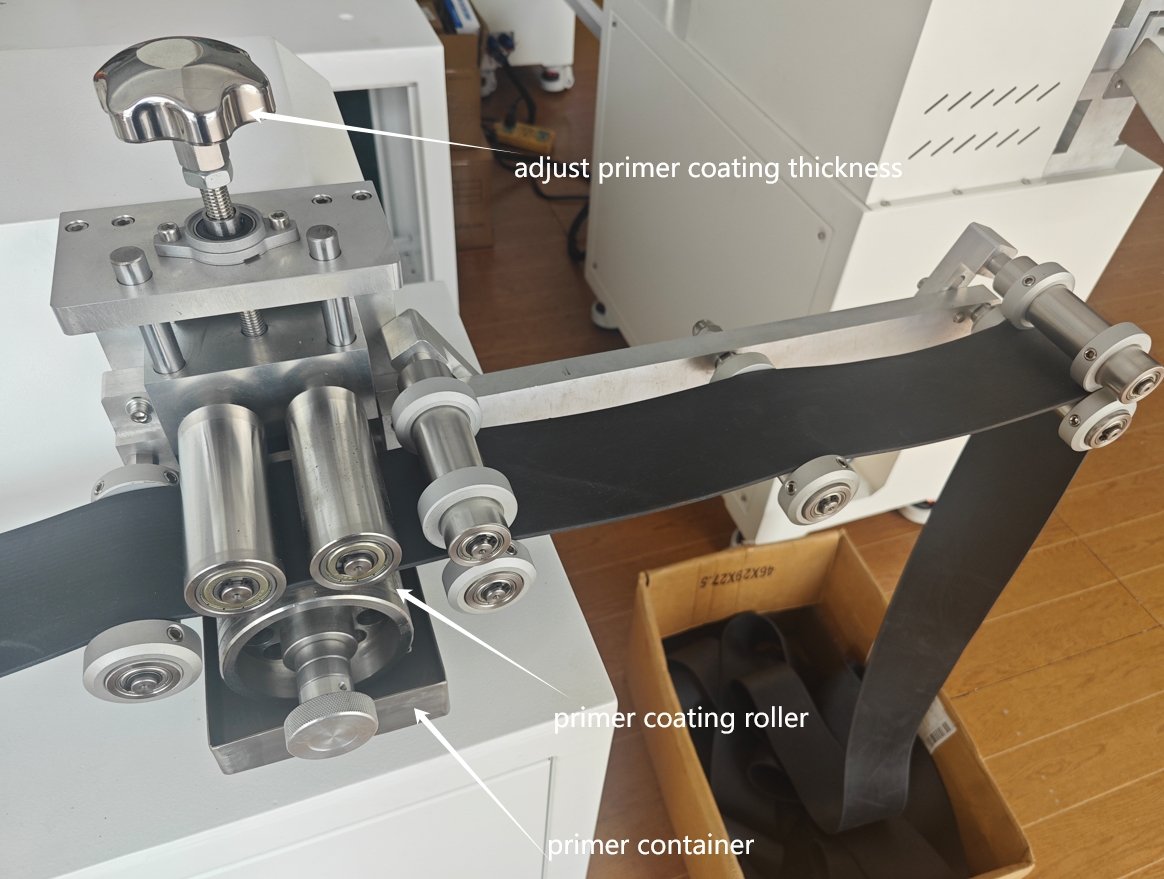

4,Roller coating primer , this adhesive silicone sealing tape laminating machine applies with roller coating primer method

which the primer is dipped on the roller from the container and coat on the rubber and silicone surfaces ,the primer coating amount

is controller by the roller pressure which can be adjusted .

5, Touch screen ,this self-adhesive gasket tape laminating machine applies with touch screen control which is easy to operate

customer can set cutting length , total cutting amount and lamination speed at will .

Front View

Side View

Side View

【Warranty 】

As an adhesive silicone rubber strip laminating cutting machine supplier , all the spare parts of the machine will have one year of free maintainance

by changing the spare parts for free and free shipping of spare parts to overseas clients starting from the issuing date of commercial invoice

after on line diagnosis .

【Packing】

1Set/Wooden case ,foam paddings will be put inside wooden case for safe overseas shipping

Home

Home

Inquiry Now

Inquiry Now Download

Download