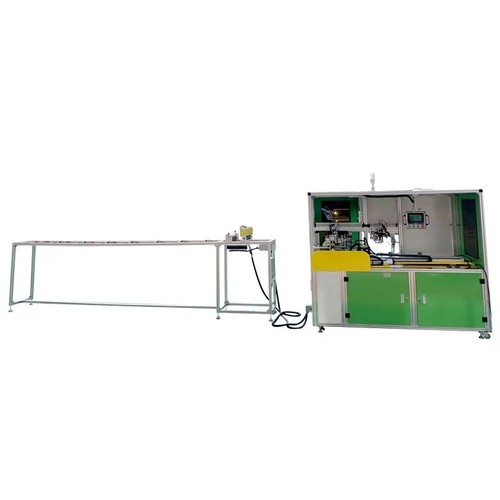

Silicone o ring automatic cutting and jointing machine ES-060

(Maximum 1.5 meter cut length type )

The silicone o ring automatic cutting and jointing machine is designed for fully automatically cutting and joining multi pieces of extruded siliocne into o rings with high productivity and labour saving

This silicone rubber gaskets automatic jointing machine combines drawing silicone gaskets to fixed cutting length +Cutting of gaskets + ,dipping silicone gaskets with silicone adhesive + Put glue dipped gaskets in the hot mold + bonding silicone into o ring gaskets +collection hand take gaskets into collection boxes in one machine

15 pieces of silicone o ring gaskets are processed at one time with great productivity achieved , all the gaskets material are fed from a feeder from behind and every gaskets are fed straightly with fixtures alignments

Youtube video

The maximum cutting length is 1.5 meter for this machine and it applies PLC touch screen controls which is easy to operate , this silicone o ring seals fully automatic cutting and jointing machine is 5kw power and the motor is servo motor from brand HCFA and the pnematics from brand AirTAC in taiwan and the machine is also equipped with alarm system ,every alarm will have code and by knowing the code ,we can trace directly to the problem and solve the problem in fast manner .

Customer can set the unit cutting length of silicone o ring gaskets on this silicone o ring automatic fusing machine , adhesive intake amount ,adhesive brushing times , gaskets dipping adhesive times based on the sizes silicone gasket , heat time and heat temperature etc.

The machine is made of feeder part and cutting and bonding machine part , the feeder part had been equiped with fixtures and sensor , every gaskets had to go through an individual fixture and sensor , the sensor will sense any pulling from beneath and sign the feeder motor to feed in more silicone gaskets and avoids tangles and knots , smooth feeding process. the feeder part is important and key for smooth processing of mult silicone o ring gaskets .

The silicone o rings which are processed by the silicone o ring automatic cutting and vulcanizer machine ES-060 are strong bonding strength above 15 N and nice joints with precisely made cavity molds and small cutting length tolerance with length drawing method by the clip hands . this silicone rubber gaskets automatic jointing machine greatly lifts productivity for silicone extrusion manufacturers which manufacture high volume silicone o ring gaskets .

【Technical Data】

Product name : The Silicone o ring automatic cutting and jointing machine

Brand : ESMAI Feature : Automatic cutting and bond extruded silicone into o ring gaskets

Model No.: ES-060 (1.5M ) Voltage: 110V/220V

Power: 5KW Working efficiency : Process 10-15 pieces of gaskets at the same time(based gasket size)

Net Weight: 805kg Cutting length tolerance:within length500mm±2,within length1000mm±3

Dimension L*W*H:7000(7800)X1800X1800mm Automation support : Servor motor ,High precision lining guide rail and silk bar.

Air source : 0.6-0.8MP Control system : PLC and touch screen

Maximum cutting Length: 1.5 meter Productivity: 20000-36000pcs per day(based on the cutting length and gaskets size,10hour a day)

【Product Advantage】

1, High productivity of 20000-360000pcs of silicone o ring gaskets (350 -500 mm cutting lenght silicone gaskets as example) can be made from the machine with

10- 15 pieces of silicone o ring to be bonded at the same time

2, Draw silicone gaskets to fixed cutting length +Cutting of gaskets + ,dipping silicone gaskets with silicone adhesive + Put glue dipped gaskets in the hot mold +

bonding silicone into o ring gaskets +collection hand take gaskets into collection boxes in one machine

3, Precision cutting length with small cutting length tolerance and nice joint of silicone o ring gaskets with good bonding strength above 15 N

【Product Details】

1,Fixtures on the feeder shelf , every gaskets pass through one individual fixture and they are straight line

and do not cross each other which made 15pcs to be processed possible

the screw is fastened for easy loading the gaskets on the machine .

2,Feeding wheels and sensors , the feeding equipment involves 15 feeding wheels ,each wheel is responsible

for feeding one individual gaskets ,the wheel will press down and roll the gaskets foward when the sensor wheels

in front are pulled up by the gaskets material

3, Two mechanical hands ,the two mechanical hands are made with cavities which fit sizes of silicone gaskets ,

they are responsible for drawing cutting length of silicone gaskets and dipping the silicone gaskets ends

with silicone adhesive (adhesive dipping times can be set on the machine) as well and place the silicone gaskets in the hot mold

4, Glue brush boards , the silicone gaskets ends will dip against the glue brush boards , the glue brush board

will be brushed with the glue for once after gaskets dipping glue and dipping glue times can be set on the

machine , normally both ends of silicone gaskets will be dipped with glue for twice .

the adhesive container holds the glue and will release the glue to brush boards by air pressing force .

the silicone adhesive as in paste form will adhere to the brush boards after brusing on .

5 ,Middle supporter , the middler supporter will automatically rise up when the long cutting length

of gaskets are drew and avoids gaskets material from weighing down in the middle and consequently

reduce cutting length tolerance

6,Hot mold&collection hand ,the hot mold move foward to take the gaskets from the mechanical clip hands

and heat cure the silicone adhesive for bonding and move back to hand over the gaskets to collection hands .

7,PLC Control screen , PLC touch screen is easy to operate ,english , spainish ,turkish ,customised

operation language is available .

8,Collection of the bonded silicone o rings , the bonded o rings will be dropped to the transport bands

the transport band will move bonded o rings to collection boxes , the collection box will collect the

silicone o rings and direct for packing up

Front View

Side View

Side View

Back View

【Warranty 】

As a silicone o ring automatic cutting and jointing machine supplier , all the spare parts of the ES-060 machine will have one year of free maintainance

by changing the spare parts for free and free shipping of spare parts to overseas clients starting from the issuing date of commercial invoice after on line diagnosis .

【Packing】

1Set/Wooden case ,foam paddings will be put inside wooden case for safe overseas shipping

Home

Home

Inquiry Now

Inquiry Now Download

Download