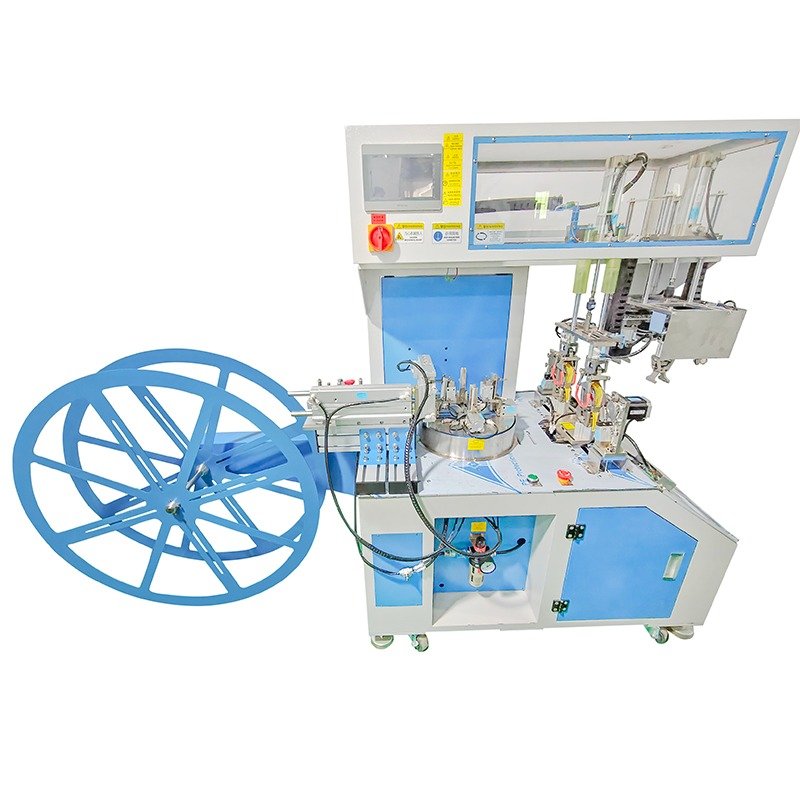

Silicone rubber tubing coiling bundling machine ES-054-1

The silicone Rubber Tubing Coiling and Bundling Machine ES-054-1 is an advanced, fully automated solution designed for efficiently handling the coiling and bundling of silicone and rubber tubing, This machine integrates auto-feeding tubes, auto-coiling tubings, and auto-bundling tube rolls , all within one machine which is labour saving and high productivity .

This automatic tube coiling bundling machine uses a double-binding method on both sides to secure both ends of the tube rolls, ensuring firm bundling.

Youtube video

One minute to understand how it works

Production video

Coiled and bundled silicone and rubber tubes

this Tubing spool bundling machine accommodates tubes with diameters ranging from 2mm to 6mm, and customizable sizes are available. The tube roll lengths can vary between 1-8m for small diameter tube and 1-3m for bigger diameter tubes ,The bundling diameter is ≤40mm, ensuring tight and secure bundling for various tube sizes.

The production speed reaches up to 700 pieces per hour, based on a 1-meter tube length with three circles coiled ,the coiling circle inner diameter is between 100mm and 200mm, commonly at 150mm or 180mm. this silicone tubing coiling and binding machine uses rubber-coated iron core wires for bundling, with a load capacity of up to 7.5 kg of bundling wires .

The Coiling diameter, height, and length, as well as production speed, can all be set on the touch screen. The head and tail tube roll ends’ remaining length can also be adjusted to meet specific requirements.

The coiled and bundled tube roll is firm bundling in good order and precise cutting length ,with this full automated solution for coiling and binding silicone and rubber tube rolls, this Silicone Rubber Tubing Coiling and Bundling Machine is ideal for customer's tube roll making businesses which it helps to lift up productivity and saves labour to do it manually .

【Technical Data】

Product name :Silicone rubber tubing coiling bundling machine

Model No.: ES-054-1

Tube roll bundling method: double-tied circle both side tube rolls

Applicable tube diameter :2-6mm (can be customised)

Applicable tube roll length :1-8m two-way tube

Applicable tube roll length :1-3m three-way tube

Bundling diameter ≤40mm

Production speed ≤700PCS/H (based on 1 meter of tube length, 3 circles with head and tail left)

Tube circle inner diameter 100-200mm (fixed at the factory, generally 150 or 180)

Head length: 80-150mm

Tail length :60-150mm

Applicable bundling wire: rubber-coated iron core

Bundling wire load ≤7.5KG

Air pressure requirement: 0.5-0.65Mpa

Machine size: L1450*W800*H1600

Machine weight: 260KG

【Product Advantage】

1,Auto feeding material + auto coiling tube into roll + auto bundling tube roll with bunlding wires in one machine ,

labour saving and high productivity .

2,Precise cutting length &bunding tube roll on both sides to form a firm bundled tube roll

3,Coiling circle diameter , coiling height and coiling length,production speed can be set on the machine based on requirement and also the head and tail tube roll ends remaining length can also be set at will .

【Product Details】

1,Holder boards &feeding roller , this automatic tube coiling bundling machine had been backed with large holder boards to hold roll material

which is easy and smooth for releasing to feed material . the holder width can be adjusted

There are multi material fixture roller which allows the tube material are fed in an alignment .

2 ,Winding system , the silicone and rubber tubing material will be fowarded to winding system by the cutting&clipping hands

the winding circle diameter can adjusted from small circle to big cirlce based on tube roll circle diameter , it also had ranking function

by adjusting winding height.

3, Wrapping system, the holder clip will take the winded tube rolls from the winding system to the wrapping hands

where the tube rolls will be wrapped with bundling wires .after the wrapping hands take over the tube rolls ,it will

foward to bundling zone .

feeding bundling wire to length ,the bundling length can be set on the machine .

4,Bundling hands , this silicone tubing coiling and binding machine applies with two bundling hands which

will bundle up tube rolls by rotating the bundling wires ,bunding cirlce can be adjusted .

bundling wires is placed inside the machine .

5, Touch screen ,this hose winding and bundling machine applies with PLC touch screen control which the cutting length

tube roll circles ,production quantites , tube roll ends remaining length , production speed etc .can all be set on the machine

Front View

Side View

Side View

【Warranty 】

As a silicone rubber tubing coiling bundling machine supplier, all the spare parts of the machine will have one year of free maintainance

by changing the spare parts for free and free shipping of spare parts to overseas clients starting from the issuing date of commercial invoice

after on line diagnosis .

【Packing】

1Set/Wooden case ,foam paddings will be put inside wooden case for safe overseas shipping

Home

Home

Inquiry Now

Inquiry Now Download

Download