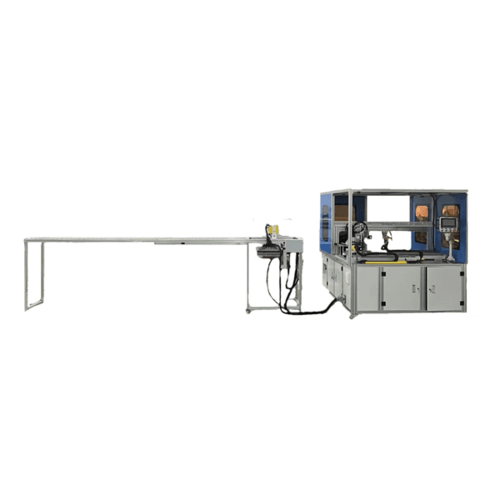

Silicone o ring fully automatic cutting and bonding machine ES-060

The silicone o ring fully automatic cutting and bonding machine is designed for cutting the extruded silicone into length , dipping the silicone gaskets ends with silicone adhesive and joining them in the hot mold to make a silicone o ring gasket in one machine .

The silicone tube cords gaskets fully automatic heat press joining machine can process 10- 15 pieces of silicone o ring gaskets at one time with right gaskets cavities

made on the mechanical hands and hot mold which is of great productivity and save labour costs for large silicone o ring gaskets manufacturers. similar sizes and similar

shore hardness silicone gaskets can be bonded on one set mold which save customer labour to change to new molds for bonding different sizes silicone gaskets .

Youtube video

Customer can set the unit cutting length of silicone o ring gaskets on the silicone o ring gaskets cutting and splicing machine , adhesive intake amount ,adhesive brushing times , gaskets dipping adhesive times based on the sizes silicone gasket , heat time and heat temperature etc ,

The machine applies PLC touch screen controls which is easy to operate , this silicone o ring seals fully automatic cutting and jointing machine is 5kw power and the motor is servo motor from brand HCFA and the pnematics from brand AirTAC in taiwan

The machine is made of feeder part and cutting and bonding machine part , the feeder part had been equiped with fixtures and sensor , every gaskets had to go through an individual fixture and sensor , the sensor will sense any pulling from beneath and sign the feeder motor to feed in more silicone gaskets and avoids tangles and knots , smooth feeding process. the feeder part is important and key for smooth processing of mult silicone o ring gaskets .

The siliccone o ring gaskets cutting and splicing machine can cut and join multi silicone o ring gaskets fully automatically and make the joints nice and bonding strength is good , the machine greatly raise productivity and save labour costs for large silicone o ring gaskets manufacturers compares to simply bond silicone o ring gaskets manually .

【Technical Data】

Product name : The silicone o ring fully automatic cutting and bonding machine

Brand : ESMAI Feature : Automatic cutting and bond extruded silicone into o ring gaskets

Model No.: ES-060 Voltage: 110V/220V

Power: 5KW Working efficiency : Process 10-15 pieces of gaskets at the same time(based gasket size)

Net Weight: 710kg Cutting length tolerance:within length500mm±2,within length1000mm±3

Packing Dimension L*W*H:7000(7800)X1800X1800mm Automation support : Servor motor ,High precision lining guide rail and silk bar.

Air source : 0.6-0.8MP Control system : PLC and touch screen

Maximum cutting Length: 1meter (1.5 meter for new type machine) Productivity: 20000-36000pcs per day(based on the cutting length and gaskets size,10hour a day)

【Product Advantage】

1, Fully automatic cutting extruded silicone ,dipping silicone gaskets with adhesive and bonding silicone into o ring gaskets in one machine

2, High productivity of 20000-360000pcs of silicone o ring gaskets (350 mm cutting lenght as example) can be made from the machine with

10- 15 pieces of silicone o ring to be bonded at the same time

3, Similar sizes and similar shore hardness silicone o ring gaskets can be bonded at the same time on one set hot mold .

4, Precision cutting length and nice joint of silicone o ring gaskets with good bonding strength

【Product Details】

1,Feeding equipment , the feeding equipment involves the shelf to hold and lead multi gaskets for processing , feeder motor

and sensor beneath it . normally all customer's silicone gaskets , each gasket will go through the feeding motor channel ,

10-15 channels on the mold can be made which means the machine can process 10-15 pieces silicone gaskets at the same time .

Each gasket goes through a sensor down there ,if any tension or pulling ,the feeder motor will send gaskets automatically

which ensures smooth feeding of multi silicone gaskets .

2, Two mechanical hands ,the two mechanical hands are made with cavities which fit sizes of silicone gaskets ,

they are responsible for drawing cutting length of silicone gaskets and dipping the silicone gaskets ends

with silicone adhesive (adhesive dipping times can be set on the machine) as well and place the silicone gaskets in the hot mold .

3, Apply the silicone adhesive , the adhesive container holds the mixed silicone adhesive ,they are mostly gel parts

and can be brushed and attach on the metal bar , the intake of adhesive is by air pressure ,customer can set how many

brushing times for one air pressing intake of silicone adhesive ,the metal bar are brushed with a thin coating of silicone

adhesive for even distribution and right dipping amount of silicone adhesive on the silicone gaskets

There are two adhesive dipping zone for dipping both gaskets ends with silicone adhesive to ensure

for a good and strong bond of silicone gaskets

4,Hot mold&collection hand ,the two mechanical hands places the silicone gaskets in the mold and the

the hot mold with right gaskets cavities made can join the silicone o ring nicely by heat pressing the joints and

get silicone adhesive cured fastly and get a strong and nice bond of silicone o ring gaskets

5,PLC Control screen , the machine will be easy to operate with PLC touch screen. enligh version available.

Front View

Side View

Side View

Back View

【Warranty 】

As a Silicone o ring fully automatic cutting and bonding machine supplier , all the spare parts of the ES-060 machine will have one year of free maintainance

by changing the spare parts for free and free shipping of spare parts to overseas clients starting from the issuing date of commercial invoice after on line diagnosis .

【Packing】

1Set/Wooden case ,foam paddings will be put inside wooden case for safe overseas shipping

Home

Home

Inquiry Now

Inquiry Now Download

Download