Silicone tube profile high precision bevel cutting machine ES-058-1

The Silicone tube profile high precision bevel cutting machine ES-058-1 is designed for automatic bevel angle cut silicone tubes and irregular silicone profiles with smooth and flat cutting edge which make it easy for subsequent corner joint into frames. This process replaces traditional raw silicone compression molding and bonding silicone corner method which is higher efficiency while reducing production costs. this machine can also widely applicable to PVC PE TPE PU silicone sealing strip/profile and other soft materials .

This machine can be directly connected to the silicone extruder with speed synchronization and variable frequency adjustment to form a complete production line from extrusion to get a cut to length gaskets .

Below youtube video to understand the machine working process .

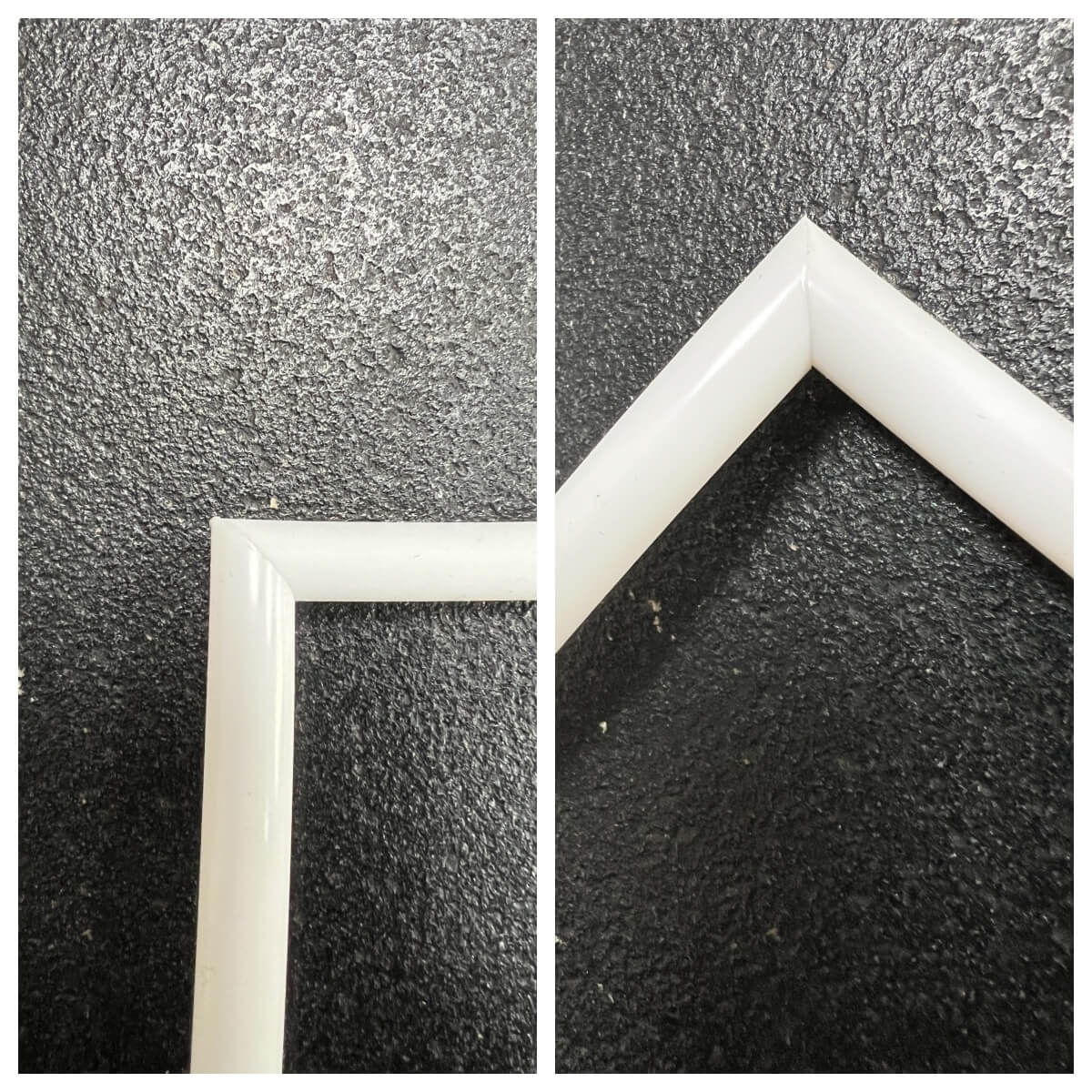

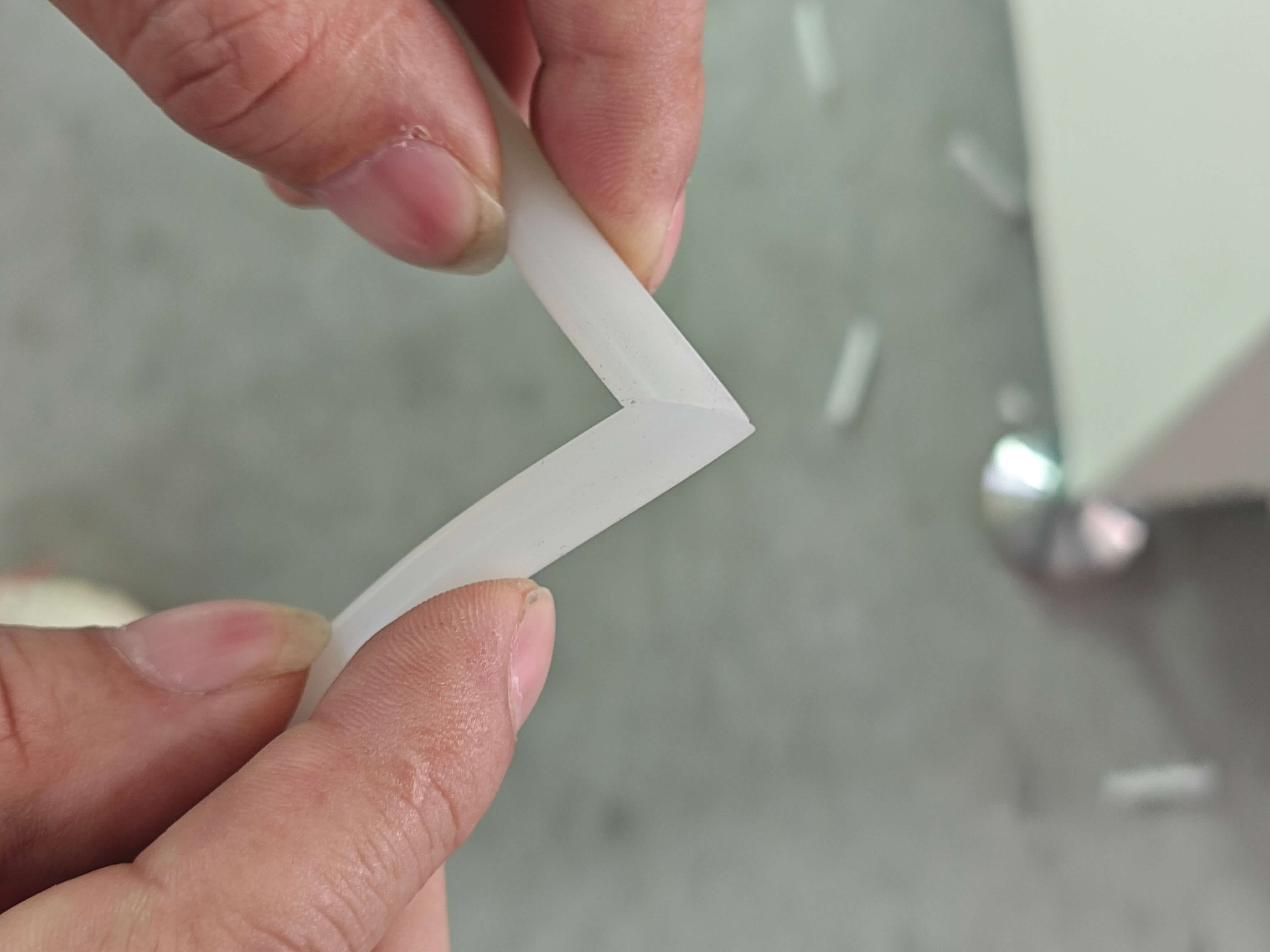

Bevel angle cut of smooth flat cutting edge & good for subsequent seamless corner joint into frame gaskets

A 2-meter conveyor table and air-blowing device is equipped in front of this Silicone tube profile high precision bevel cutting machine which it blows off the issuing cut to length gaskets to collection zone in good

order and a feeder device is placed at the back to feed gasket material automatically which ensures smooth feeding process .

The cutting length ranges 20MM-99999MM (Freely adjustable), for good bevel cutting ,the tube profile wall thickness should be above 0.25MM, Tube OD sizes ranges 2.5-35mm . the machine power is 3.3KW , the entire working system applies with servo motor for precision cutting length up to 1000+_mm

This rubber automatic bevel cutting machine can achieve a consumption cutting of 95 meters per minute or 2000 cuts per minute for short length cut featuring with high speeding cutting for straight cutting mode

The equipment has great compatibility, allowing for different specification gaskets profiles to be bevel cut by changing the mold fixture , The cutting angle can be freely set via touch screen interface, and the program supports storage and one-click prameter receipe retrieval which is convinent to use .

The best advantage of this silicone tube profile high precision bevel cutting machine is that the bevel cut edge is perfectly smooth and flat which enable the bevel cut gaskets to join into seamless corner by the semi automatic bonding machines . it will replace the traditional method with compression molding raw silicone onto the corner joint which is low efficent and higher labour cost and unncessary post trimming on the joint.

【Technical Data】

Product name: Silicone tube profile high precision bevel cutting machine

Model No.:ES-058-1

Voltage: 220V-AC

Frequency : 50/60HZ

Power 3.3KW

Display :7-inch color TFT

Material feeding efficiency :95 meters/minute& 2000pcs /min high speed cutting for short length

Touch screen : PLC/touch screen

Processing tube outer diameter φ2.5/φ35 (making fixture mold)

Cutting length: 20MM-99999MM (free setting)

Cutting length tolerance : 1000mm+-1mm

Cutting material : PVC PE TPE PU silicone sealing strip/profile and other soft materials (special shape gaskets need to add auxiliary devices)

Tube/profile thickness : 0.25MM or more

Operating temperature 0℃-50℃

Air pressure requirement 0.5-0.8Mpa

Operating humidity 10%RH~90%RH (no condensation)

Anti-interference ability Interference voltage: 1500Vp-p

Pulse period: 1us Duration: 1 minute

Cooling method :Forced air cooling

Dimensions :1070*700*1450MM

Machine net weight :265KG

【Product Advantage】

1,Cutting silicone tubes and irregular profiles into a beveled, smooth edge, making it easier for subsequent corner joint into frames.

This process replaces traditional raw silicone compression molding and bonding method , our method is higher efficiency while reducing production costs.

2, All kinds angle cutting patterns to be cut , any bevel angle degrees can be set on the machine .

3, Cutting length controlled within +_1mm &high speed cutting , utilizing electronic cam closed-loop control technology to achieve high-speed, high-precision cutting,

the entire system applies with high-power servo motors.

4, High speed cutting of 2000 pcs per minute for straight cutting mode

5, Alarms sounded when production quantity is reached to remind workers to load new material and enable one person to operate multiple machines,

greatly reducing labor costs.

【Product Details】

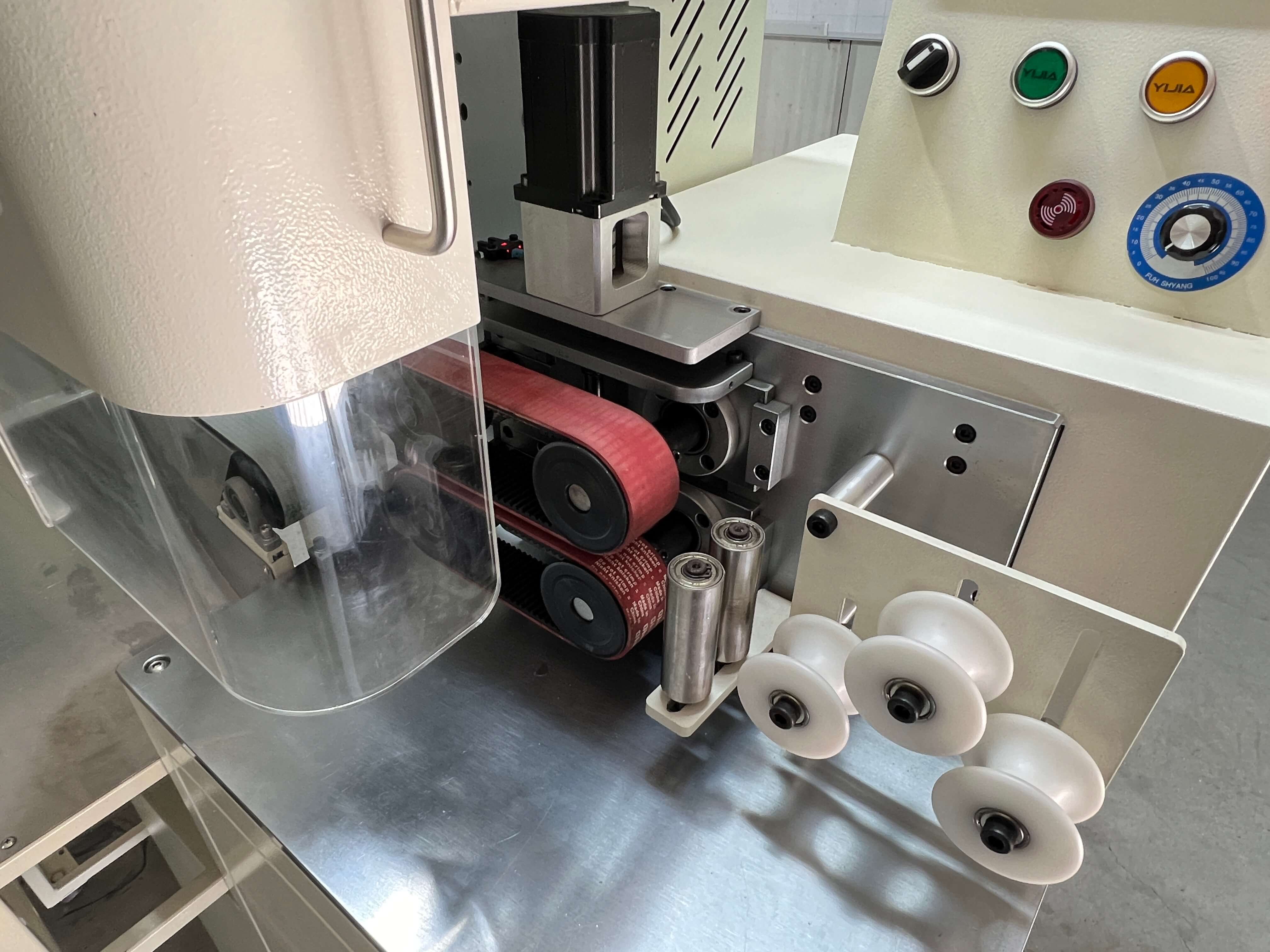

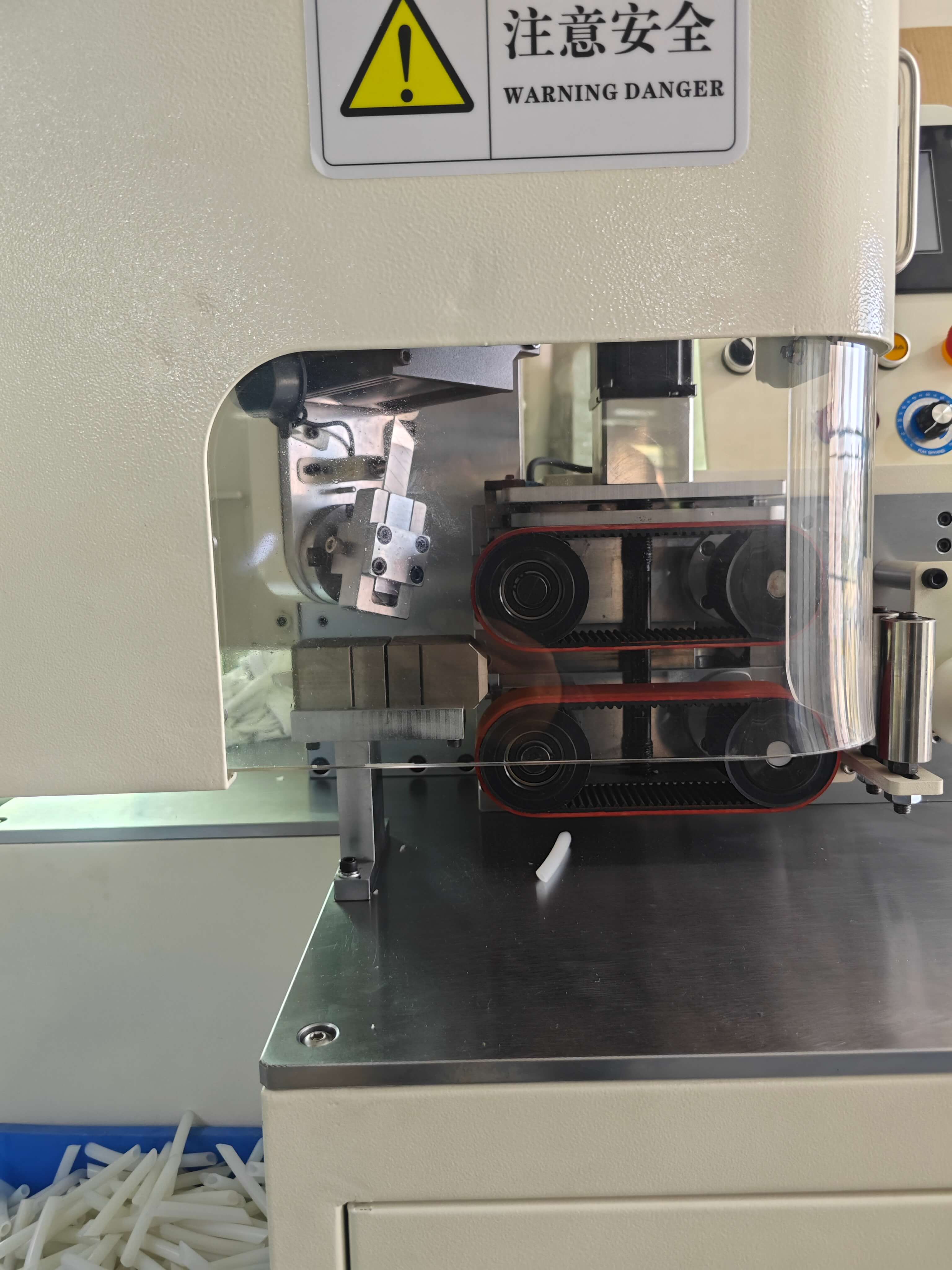

1,Double transport belt bands & Bevel angle cut knife , this silicone tube bevel cutter machine applies with double transport belt bands to transport

silicone profiles and silicone tubes , the driving motor is servo motor which ensures high precision length transporing ,

the double transport belt bands distance can be ajusted to hold different size profiles and tubings .

The bevel angle cut knife is driven by high power motors and high speed cutting , this ensures the cuting edge of irregular shape silicone profiles is also

smooth and flat and will be good for joining into corner frames .

2 ,Feeder with sensor ,there is a feeder device at the back of the silicone profile high precision bevel angle cutter machine , it can

sense dropping and pulling of silicone gaskets material , when gaskets tends to drop down , it reduce feeding speed or stop feeding

,when gaskets goes up , it increases feeding speed to avoid pulling tension of gaskets during feeding process . this function will ensure

cutting length precision and avoid cutting length tolerance .

3, Collection blowing device , the bevel cut to length gaskets will be blown off to collection zone which is good for collection , there is a also transport belt

band on top of the collection device , it will support and transport cut to length gaskets foward , the cut to length gaskets weight is supported

so it will also avoids pulling from front and further maintains cutting length precison .

4, PLC Touch screen, this rubber automatic bevel cutting machine applies with PLC touch screen which is easy to operate, customer can set

the cutting length ,cutting quantity , bevel angle cut degrees , cutting and feeding speed can all be set on the machine.

Side View

Side View

Side View

【Warranty 】

As a silicone tube profile high precision bevel cutting machine supplier , all the spare parts of the machine will have one year of free maintainance by changing the spare parts for free

and free shipping of spare parts to overseas clients starting from the issuing date of commercial invoice after on line diagnosis .

【Packing】

1Set/Wooden case ,foam paddings will be put inside wooden case for safe overseas shipping

Home

Home

Inquiry Now

Inquiry Now Download

Download